Transporting earthmoving equipment can be a daunting task, but it’s a crucial component in ensuring that construction projects run smoothly and efficiently. Whether you’re a construction company, an equipment rental business, or a logistics professional, understanding the nuances of moving heavy machinery can save time, reduce costs, and minimize risks. This blog post will guide you through the ins and outs of earthmoving equipment transport, providing practical tips, real-life examples, and insights into future trends.

Understanding the Types of Earthmoving Equipment

Earthmoving equipment comes in various shapes and sizes, each with its own set of transportation challenges. Bulldozers, excavators, loaders, and backhoes are among the most common types used in construction. These machines vary significantly in terms of weight and dimensions, which directly affects the transport method chosen.

First, consider the immense weight of these machines. A standard bulldozer can weigh anywhere from 8 to over 100 tons, depending on its size and function. Similarly, excavators and loaders have wide ranges, often tipping the scales at several tons. This weight makes their transportation a logistical feat, requiring specialized vehicles.

Next, the dimensions of these machines add another layer of complexity. The width and height of equipment like loaders and backhoes can necessitate permits for oversized loads, as well as special planning to avoid obstacles like low bridges. Understanding these specifications is crucial for efficient and legal transport.

Finally, consider the equipment’s functionality. Many earthmoving machines have movable parts, like arms and blades, which must be secured during transit. Ensuring these are properly immobilized prevents damage and enhances safety, both for the equipment and other road users.

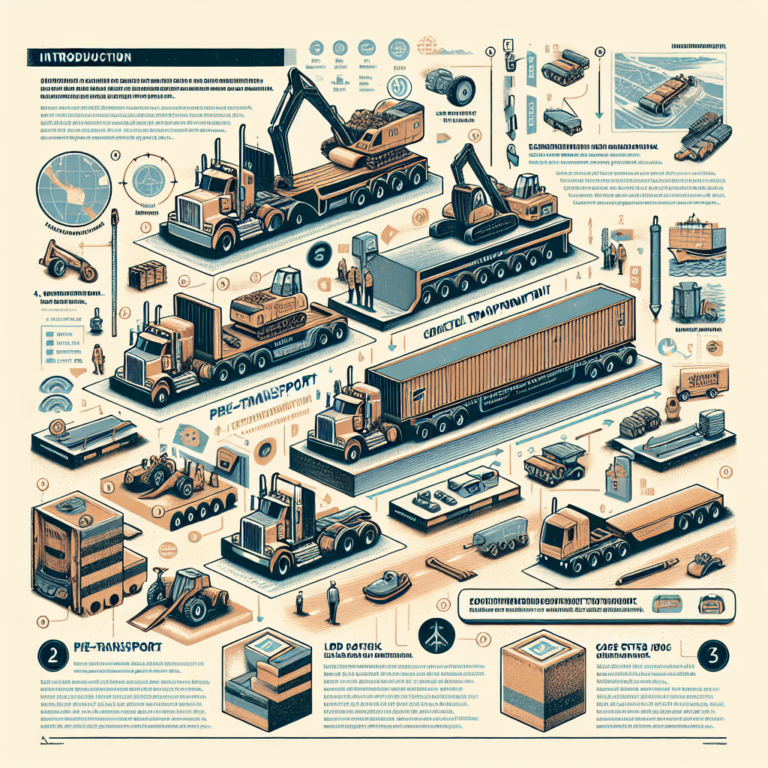

Pre-Transport Checklist for a Smooth Journey

Before embarking on the transportation of earthmoving equipment, a detailed pre-transport checklist is essential. This preparation phase helps ensure that everything runs smoothly, minimizing the risk of accidents or delays.

Begin with a thorough inspection of the equipment. Look for any existing damage or maintenance issues that transport might exacerbate. Addressing these beforehand can prevent more severe problems down the line and ensure the machine is in optimal condition upon arrival.

Next, secure all movable parts. Use chains, straps, and locks to keep parts like excavator arms or bulldozer blades in place. Properly securing these components is vital for safety, as it prevents shifting that could lead to accidents or equipment damage.

Finally, document the equipment’s condition. Take photographs and record details of its state before transport. This documentation is invaluable for insurance purposes and helps resolve any disputes if damage occurs during transit.

Choosing the Right Transportation Method

Selecting the appropriate transportation method for earthmoving equipment depends on several factors, including the size, weight, and destination of the machinery. Here, we’ll explore some common options and weigh their advantages and disadvantages.

Flatbed trucks are a popular choice for transporting smaller equipment. They offer flexibility and ease of loading but may not be suitable for oversized loads. The relatively low cost and simplicity make flatbeds appealing for short distances and lighter machinery.

Lowboy trailers, with their lowered deck, are ideal for carrying larger and heavier equipment. They provide stability and accommodate taller machines by reducing overall height. However, the specialized nature of lowboy trailers often means higher costs and the need for additional permits.

In some cases, container shipping may be the best option, especially for international transport. This method offers protection from the elements and can streamline customs processes. However, it requires precise measurements to ensure the equipment fits within standard container dimensions.

Legal and Safety Considerations in Earthmoving Equipment Transport

Transporting heavy equipment isn’t just about logistics; it also involves adhering to a myriad of legal and safety regulations. Compliance with these rules is not only a legal obligation but also a fundamental aspect of ensuring a smooth and incident-free transportation process.

First, understand the permits required for your transport. Depending on the location and size of the equipment, you may need permits for oversized loads. These documents are crucial for legal compliance and avoiding fines or delays.

Next, familiarize yourself with weight limits and restrictions on certain roads or bridges. Overloading a vehicle or exceeding a roadway’s capacity can lead to severe penalties and potential safety hazards. Planning routes in advance helps avoid these issues.

Lastly, prioritize safety for both the equipment and those involved in its transport. Ensure all personnel are trained in handling heavy machinery and are aware of the specific safety protocols for loading and unloading. This preparation minimizes the risk of accidents during the transport process.

Real-Life Case Studies of Successful Transportation

Learning from real-life examples can provide valuable insights into the challenges and solutions involved in transporting earthmoving equipment. Here, we look at a few case studies that highlight innovative approaches and successful outcomes.

One construction company faced the challenge of moving a fleet of excavators across a mountainous region. By employing modular platforms and staggered transport schedules, they effectively managed the terrain’s difficulties, ensuring timely delivery and operational efficiency.

Another equipment rental business optimized its transport process by investing in GPS and telematics technology. This allowed for real-time tracking of equipment and better coordination with transport teams, reducing delays and enhancing overall efficiency.

A logistics firm successfully transported a massive bulldozer internationally by disassembling it into smaller components. This approach minimized shipping costs and streamlined customs procedures, offering a creative solution to complex regulatory challenges.

Future Trends in Heavy Equipment Transportation

The transportation of heavy equipment is poised for significant changes as technology and industry practices evolve. Understanding these trends can help businesses stay ahead and optimize their logistics processes.

Automation and AI are expected to play a larger role in equipment transport. These technologies can enhance route optimization, improve safety through predictive maintenance, and streamline the entire logistics process, reducing costs and increasing efficiency.

Sustainability is becoming a growing priority in the industry. Innovations such as electric transport vehicles and eco-friendly packing materials are gaining traction, helping companies reduce their carbon footprint and meet environmental regulations.

Finally, digital platforms are revolutionizing the way businesses manage logistics. From advanced tracking systems to seamless communication tools, these technologies are enhancing coordination and transparency, paving the way for more efficient transport operations.

Best Practices for Heavy Equipment Loading and Unloading

The loading and unloading of heavy equipment are critical stages in the transportation process, requiring careful planning and execution to ensure safety and efficiency. Firstly, always assess the loading area for suitability, ensuring it is level, stable, and free from obstacles. This simple precaution can prevent accidents and facilitate smooth operations.

Employ the use of ramps or platforms specifically designed for heavy machinery. These should be constructed to support the weight of the equipment and provide a safe slope for loading. When moving equipment onto a transporter, ensure that the machinery is in good operating condition, with all controls functioning correctly and operators familiar with the equipment’s capabilities.

Next, establish clear communication among all personnel involved in the loading and unloading process. Implementing hand signals or using radios can ensure that everyone understands their roles and is aware of movements during the operation, thereby minimizing risks. Additionally, always use proper personal protective equipment (PPE) for all workers involved, adhering to safety regulations to reduce the likelihood of injuries.

Lastly, before transporting heavy equipment, double-check that all securing mechanisms—straps, chains, and locks—are in place and adequately tightened. A thorough inspection of the loaded equipment helps prevent any shifting during transport, protecting both the machinery and the transport vehicle. By adhering to these best practices, companies can safeguard their assets while enhancing operational efficiency in heavy equipment transportation.

Conclusions: Efficient Earthmoving Equipment Transport

Efficiently transporting earthmoving equipment is a complex but essential task for construction companies, equipment rental businesses, and logistics professionals. By understanding the diverse types of machinery, preparing meticulously, and choosing the right transport methods, businesses can streamline their operations and reduce risks.

Legal and safety considerations remain paramount, and staying informed on regulations ensures smooth and compliant transport. Learning from successful case studies offers practical insights, while keeping an eye on future trends prepares businesses for an evolving industry landscape.

For more detailed guides, explore our Heavy Equipment Maintenance Guide, discover the Top Earthmoving Equipment of 2022, or learn how to Maximize Equipment Efficiency with Logistics Technology. Feel free to share your experiences or questions in the comments below!

Key Considerations for Selecting Transport Methods

Selecting the appropriate transport method for heavy equipment is pivotal in ensuring successful and efficient logistics operations. First and foremost, evaluate the nature and dimensions of the equipment. Larger and heavier machines may necessitate specialized transport solutions such as lowboy trailers or extendable flatbeds, which can accommodate their weight and size while ensuring stability during transit.

Another critical factor is the transport route. Analyze potential routes for any obstacles, such as weight restrictions on bridges, narrow roads, and low-clearance areas. Mapping out alternative routes beforehand can prevent unexpected delays and complications during the journey. Additionally, consider the timing of transport to avoid peak traffic hours, which can further impede smooth logistics operations.

Furthermore, it is essential to maintain open lines of communication with transport providers. Establishing a partnership with reliable logistics companies that have a proven track record in heavy equipment transport can mitigate risks and enhance reliability. Regularly review agreements and compliance with safety standards to ensure mutual understanding and adherence to best practices. By strategically selecting transport methods, businesses can optimize their logistics, reduce costs, and ensure timely delivery of valuable equipment.