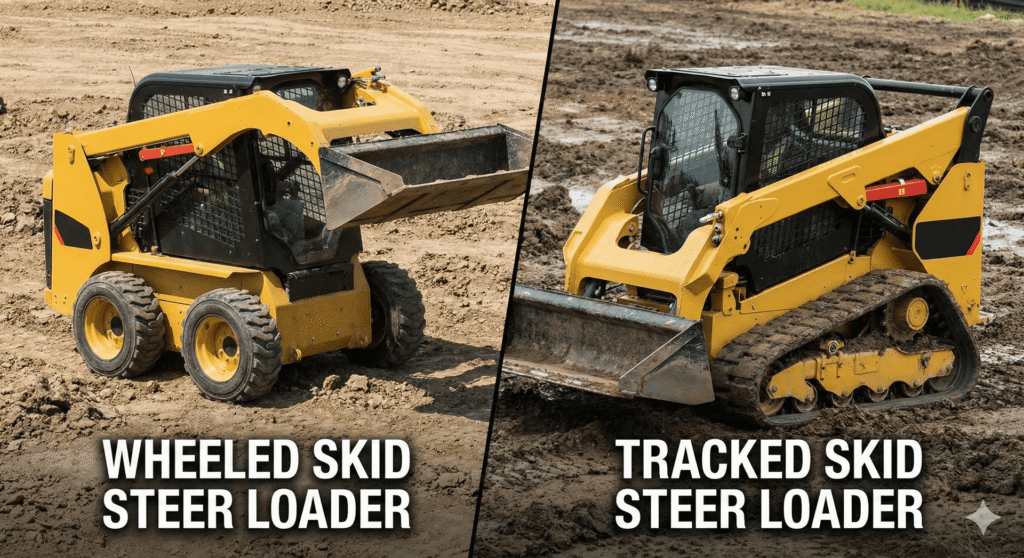

Choosing the correct Skid Steer Loader tires size affects operating economy and equipment performance. Skid loaders are versatile instruments used in construction, agriculture, and other industries, but their efficacy depends on tire type.

Many operators underestimate the benefits of integrated tires for load capacity and traction. Knowing these parameters may result in excellent performance for certain activities, depending on tire design and rim width compatibility.

Although extra safety precautions are needed, the right Skid Steer Loader tires allows smoother operations over diverse terrain, safeguarding equipment and people. When choosing a skid loader tire, it is crucial to examine the tire’s size and application-specific specifications, as it mismatch might affect maintenance costs or efficiency.

All About Skid Loader

Know the Skid Steer Loader Tires Range

Choosing the right Skid Steer Loader tires size will help your equipment to operate and run as it should. Usually it encompasses three primary dimensions—the tire width, aspect ratio, and wheel diameter. Skid Steer Loader tires measurements require a normal measurement might be 12×16.5, where “12” represents the width in inches, “16.5” represents the rim’s diameter in inches, and any aspect ratio—that is, the link between width and height—is normally implicit in these figures.

Knowing these measurement components will help you to ensure that the tires on your skid loader fit properly, therefore promoting effective operation free from unnecessary component stress.

Consider the following factors before choosing the perfect tire:

- Consult Manufacturer: Many equipment and operational conditions determine Skid Steer Loader tires size. The manufacturer’s specifications or owner’s manual will inform you the tire sizes your vehicle needs. The load capacity of your activity influences the tire durability required to handle weight while maintaining performance and safety.

- Choose the suitable Type: Larger tires could increase flotation and stability if your location is sloppily or muddy. Think your current tires and if your wear pattern or usage calls for changes. Older tires could lose traction and fuel economy due to rising rolling resistance. Thus, while evaluating Skid Steer Loader tires options, choose one that fits physically and functionally to enhance performance and reduce risks associated with incorrect size.

- Safety Check: Running safety and efficiency all around depends on knowledge of Skid Steer Loader tires size. While load capacity and job site circumstances should be considered, carefully validating tire measures against manufacturer specifications will help you to choose the correct tires that fulfill all functional requirements and support more smooth work processes over many uses.

Load Capacity: Taking Thought into Account

Load capacity of such tires is one of the most crucial factors a skid loader choosing tires should give top priority. It maintains perfect performance and safety restrictions and displays the safe weight a certain tire can bear.

If tires are not rated for the required weight, blowouts, lower traction, and finally increased operating costs due to potential vehicle damage or accidents may occur. Using under-spec tires may reduce output for heavy-duty activities such as excavation or demolition, as well as increase the danger of injury to people and machines.

Factors that Affect Skid Steer Loader Tires Load Capacity:

- Size and Pressure of Inflation: Size and inflation pressure of the Skid Steer Loader tires mostly affect their performance. Larger tire sizes generally provide greater load ratings, even if they could affect handling and mobility. Maintaining the optimum inflation pressure is also vital; under-inflation causes excessive heat and early wear, while over-inflation causes a harsh and unpleasant ride. A correct balance ensures longevity and excellent performance.

- Tread Design and Surrounding Environment: Tread design and ambient environment have a major impact on tire performance. Skid loaders benefit on uneven terrain with tires with deeper tread that efficiently disperse debris and provide constant grip in slippery circumstances. Choosing tires appropriate for the working circumstances and load requirements increases operational efficiency and safety, therefore ensuring better performance under tough conditions.

- Capacity for Load and Longevity: First focusing on load capacity will help you to ensure correct functioning of your skid loader under many conditions. When you purchase new tires, consider how load management strategies impact performance and lifetime. Making the right decisions not only improves operating efficiency but also reduces downtime and maintenance costs, therefore boosting your long-term bottom line.

In Alignment With The Rim Width:

- Importance of rim width and tire size compatibility: Mismatched sizes may lead to early tire wear and performance issues; therefore, skid loader maintenance prioritizes matching them. Safe operation requires traction, stability, and weight distribution from good tires. Mismatched rims may cause excessive flexing or stress that reduces handling and damages sidewalls.

- Determining Rim Width Compatibility: Rim fit needs knowledge of tire width and performance. Most tire producers recommend rim widths for each kind of tire. For instance, a 10-inch skid loader tire complements 7- to 9-inch rims. Rims that are excessively broad may undermine structural integrity, while rims that are too thin might cause poor handling and blowouts.

- Referencing Manufacturer Guidelines: Always follow Skid Steer Loader tires and rim manufacturer guidelines for correct fit. The load capacity and intended use frequently determine the compatible rim widths for particular tire types. Cross-referencing this data will allow operators choose the best equipment combination. It allows technical data sheets and industry experts may also aid decision-making.

Value of Tread Design in Skid Steer Loader Tires

Selecting the right tires for your Skid Steer Loader mostly hinges on tread design, as it directly affects performance and safety in different operating conditions. Different tread patterns shine in certain activities, such as digging, lifting, or negotiating uneven terrain. On uneven ground, including building sites where mobility and heavy lifting are required, aggressive lug patterns provide outstanding grip. On paved surfaces or inside applications, on the other hand, smooth treads are more appropriate to reduce surface damage and provide enough traction.

- Adjusting to Environmental Conditions: Adapting to environmental circumstances like ground conditions and temperature also depends critically on tread design. Ideal for muddy or snowy situations, when preserving grip and minimizing hydroplaning is crucial, tires with deeper grooves efficiently drain water away from the contact patch. Shallower treads, on the other hand, provide superior surface contact and ideal load-bearing capability and are more appropriate for arid surroundings. All-terrain tires with hybrid tread patterns provide flexibility without sacrificing performance for tasks involving many surfaces, including paved areas and dirt roads.

- Improving safety and stability: Specialized tread patterns—such as chevron forms or those intended for lateral stability—help balance during side-loading or cornering. Edge-heavy applications where unequal weights might cause tipping dangers depend notably on this function as Choosing appropriate tread design not only improves traction but also increases general productivity by lowering hazards, hence raising operator confidence in challenging environments.

- Safety and Financial Implications: Understanding tread design and traction requirements is critical for increasing operational efficiency and safety. A good tire choice reduces costly equipment downtime due to poor traction or early deterioration. Operators may improve performance and cost-effectiveness by matching tread and application to increase responsiveness, tire life, and traction.

Applications-Specific Tires

Choosing the appropriate Skid Steer Loader tires starts with knowing the particular uses for which the machinery will be put. Every surroundings creates different obstacles that affect tire performance. For example, building sites can have uneven ground covered in trash that calls for tires with optimum grip and longevity. In agricultural environmental scenarios, Skid Steer Loader tires are appropriate for softer terrain areas like mud or dirt. Being aware of these variances is essential for improving productivity and maintaining safety throughout operation.

- Tires for Buildings Sites: Hard surface tread patterns are usually the best option in building applications like grading or excavation. These tires provide great traction on stable terrain and withstand punctures. Particularly useful are all-terrain Skid Steer Loader tires with strong tread patterns and reinforced sidewalls, as they can withstand sharp items and rough surfaces often seen on construction sites. Their robustness guarantees consistent performance in challenging building settings.

- Tires for Use in Agronomy: Tires built especially for soft terrain help agricultural activities. For example, flotation tires provide superior grip on muddy grounds and help to reduce soil compaction. Particularly helpful are wider tires as they uniformly distribute weight over a greater surface area, therefore preserving soil condition and stability. These designs result in the perfect for agricultural chores requiring careful terrain management.

- The Value of Aligning with Needs: Matching tires to your skid loader’s operational requirements guarantees maximum performance across a variety of terrains. Skid Steer Loader tires designed for particular applications are essential for transporting huge loads on construction sites or navigating wet, uneven agricultural areas. Any business would want to invest in the correct tires as they not only increase efficiency but also safety.

Value of Using Manufacturer Guidelines

Skid Steer Loader tire lifetime and best performance depend on following manufacturer recommendations. To fit their equipment, manufacturers commit large efforts to find perfect tire sizes, load capabilities, and tread patterns. By regularly following these guidelines, we ensure that the tires perform as intended, providing the essential traction, stability, and safety in a variety of operating conditions. By using tires that do not meet prescribed standards, for example, may impair machine control and increase the risk of an accident due to poor ground adhesion.

- Effects of unequal tires: Following manufacturer recommendations helps to avoid early wear and tear on equipment parts and tires. Tires too small or too big for a given Skid Steer Loader model may cause imbalances that speed up wheel bearing wear and compromise the integrity of the drive system. Moreover, mismatched tires may boost fuel economy as engines must work harder to offset. Following recommended policies helps you not only save tire investment but also improve operational effectiveness.

- Effect on Warranties and Repairs: Ignoring manufacturer advice could cause problems with warranties and repairs. Should a fault arise and the tires utilized fall short of manufacturing standards, manufacturers might reject warranty claims and attribute the variation as the reason. Paying strict attention to recommended tire measures guarantees defense against needless repair expenses, therefore saving money resources as well as machines.

Adapting to Environmental Conditions

- Deviating from manufacturer guidelines may cause premature wear and tear on tires and mechanical components. Engine and wheel bearing problems might result from undersized or oversized Skid Steer Loader tires. This imbalance may make the engine work harder and use more gasoline. Skid Steer Loader tire specifications improve efficiency and lifespan.

- Potential Warranty Issues: Ignoring manufacturer advice may void warranties or complicate repair claims. Manufacturers may deny warranty coverage if you depart from the recommended size and detect a tire fault. Closely monitoring tire measurements may save you money and prevent pricey repairs from blunders.

- Importance of Following Manufacturer Guidelines: Using Manufacturer Guidelines’ Value Keep your skid loader functioning properly by following manufacturer instructions. From load capacity to rim width compatibility, every component affects equipment effectiveness in harsh locations like fields and construction sites. These standards decrease long-term maintenance, eliminate expensive failures, and boost production.

Financial Concerns Regarding Choice of Tire

- Managing Cost, Quality, and Lifetime: Juggling Life, Money, and Tools Skid Steer Loader tire selection calls for balancing cost, quality, and lifetime. Although selecting the least priced choice might appear desirable, over time it could be more expensive. Superior tires might finally increase work performance, efficiency, and safety. Less expensive but less durable tires might need regular repair and downtime, therefore negating early savings.

- Analyzing tire lifetime and terrain requirements: Examining tire life and terrain needs Value Terrain Requirements and Tire Life Make decisions considering average lifespan of tire types and models. Although they originally cost more, better tires last longer and are less costly over time. Purchasing tires with improved traction and durability might help save maintenance costs for uneven or severe use.

- Maintaining Tires for Longevity: Tire Repair for Durability Mostly maintenance determines how long your Skid Steer Loader tires last at an affordable price. Periodically, wear and tear studies, alignment, and inflation aid to prevent costly repairs. These standards will help you to be sure that your investment supports effective operations catered to your demand and balances cost and quality.

Effective Techniques of Skid Steer Loader Tire Maintenance

Regular maintenance guarantees the condition of your skid loader tires; hence, both longevity and maximum performance depend on it. Regular tire pressure check are a desirable practice, as under- or over-inflated tires may cause unequal wear and decreased traction. Manufacturers say that keeping the advised tire pressure will help to maximize load capacity handling and fuel efficiency. Tracking a tire’s wear pattern may also help one determine when it should be rotated or replaced.

- Visual assessments of damage and foreign objects: You really should look at the tires for weird things like nails or stones caught in the tread. Ignored, they may cause air leaks or punctures. Look for scrapes, bulges, or cuts compromising the structural integrity of the tire. Ignoring such issues might lead to detrimental effects or costly fixes. Usually, regular inspections assist in identifying early-on problems every time the skid loader is functioning.

- Indices of Tire Replacement: More important than routine maintenance is knowledge of when tire replacement is needed. A main sign is tread depth; most experts advise replacement when the depth comes to 1/4 inch (6 mm), since this affects grip and safety. Uneven wear—such as cupping or scalloping—may also point to misalignment problems that call for both new tires and also highlight the necessity of suspension changes. Careful monitoring these indicators can help you to avoid more long-term harm and conserve resources.

- Skid Loader Performance: Preventative Care Preventative maintenance is key to skid loader performance and longevity. Tread wear indicators, appropriate tire pressure, and visual checks may help drivers avoid catastrophic tire failures caused by damage. These methods eventually increase equipment performance anywhere, ensuring smooth operation and extending its lifespan.

Deciding the Right Path to Approach Peak Performance

Choosing the appropriate Skid Steer Loader tire size in the end will help you to maximize the performance and efficiency in your activities. Important elements, including tire size, load capacity, rim width compatibility, and tread design relevance, have been investigated throughout this investigation.

Every component in an agricultural or construction setting affects how your equipment runs according to certain criteria. Following manufacturer instructions guarantees dependability and safety as well as helps budget in view of financial difficulties without compromising quality.

Selecting new Skid Steer Loader tires requires careful study of your particular requirements depending on performance criteria and application guidelines. By means of best recommendations for regular maintenance, analyzing these elements in line will help you to make a decision guaranteeing your long-term operating viability. Good tires not only provide maximum return on investment but also boost output and prolong the lifespan of your equipment.