Innovative Skid Steer Attachments You Probably Never Heard Of

When the image of a skid steer loader comes to your mind, it is probably a robust yellow or white machine moving a heap of dirt with a standard bucket. It is the powerhouse of a construction site, the dependable partner of landscaping, and the unrecognized hero of farming jobs. However, simply considering a skid steer attachments as a dirt-mover is the same as using a smartphone only for making calls—you are not taking advantage of about 90% of its functionality.

The real charm of these little loaders is in their hydraulic systems and the extensive, often surprising, range of attachments that have become available nowadays. While Scissor Lifts offer vertical access to high-level jobs, the skid steer rules the ground game, and with the right innovative attachments, it can become nearly any machine you want.

The market for skid steer attachments has drastically changed from simply forks and buckets. Nowadays, entrepreneurs are coming up with highly specialized, engineered prodigies that can make a single operator capable of doing things that were the exclusive domain of large and heavy machinery.

For contractors and fleet managers, being familiar with those “hidden gem” attachments can be the difference between renting several different machines or merely changing a faceplate on the one that you already have. Here, we will take a look at some of the most innovative, obscure, and highly effective skid steer attachments that you most likely never heard of, but you will certainly want them in your arsenal once you do.

The Laser Grading Box Blade: Earthmoving with High Accuracy

One of the most highly innovative features in a skid steer is the combination of laser perfection with the conventional grading tool. The Laser Grading Box Blade completely eliminates the human error in ground leveling for concrete pads, parking lots, or playing fields. In contrast to a regular dozer blade that depends on literally the operator’s steady hand and eye, this attachment uses a laser transmitter on the job site.

The machine hydraulics automatically move the blade up or down hundreds of times a second to keep the surface perfectly flat or with the desired slope within millimeters of accuracy.

The introduction of this tool significantly alters the way in which a construction site operates. The onboard receiver converts the signal from the laser transmitter into instant hydraulic movements of the blade raising or lowering it to the correct level.

- Less Moving Around: The need for an assistant to carry out grade checking on the ground is eliminated; hence personnel can be kept out of harm’s way and a single operator can perform the work of a team.

- Cost Effective: You get the sub-base level with such great accuracy that you use exactly the amount of concrete or asphalt that has been planned, thus avoiding costly over-ordering.

The Green Thumb Tree Spade

In the past, relocating mature trees was only possible with massive truck-mounted spades that inevitably damaged the ground because of their heavy weight. Now the Skid Steer Tree Spade comes as a small but efficient attachment that allows you to dig up, move, and replant trees in no time at all. It is a system of three or four hydraulically controlled blades which are lowered into the ground around the tree, before being raised as a unit together with the tree, roots, and soil, thus maintaining the root ball and avoiding shock to the tree.

- The uses of the tree spade go well beyond simple gardening.

- Developers can move trees that have been already grown from the area of clearing to that of finishing; hence, new properties get an instant mature look.

- Tree growers can dig up stock easily, quickly, and without any manual work thus significantly raising their daily output.

- Because the cut is shaped like a cone the roots stay tight and are not easily disturbed during transport, thus the plant survival rate is increased dramatically.

The Silt Fence Installer: Make Erosion Control Simple

Installing silt fences is one of the least enjoyable tasks for any contractor in site preparation and environmental compliance. Usually, it brings to mind trenching, unrolling fabric, and manually putting stakes all around the perimeter. The Silt Fence Installer attachment makes the process a single pass job where a whole operation would otherwise have been possible.

This clever device can be attached to the front of a skid steer and cuts a trench in the soil, laying the silt fabric in the ground as it goes. Some models even come with a coulter wheel that cuts through roots and grass, making a neat installation without the surrounding area being disturbed.

The time saving aspect of using a Silt Fence Installer is out of this world when compared to doing the task manually.

- Installation in No Time: A skilled operator with a machine can accomplish in one day what a manual crew takes a week to a week and a half. In fact, the operator installing the silt fence can be credited in feet per minute and not in feet per day.

- Being on the right side of the law: The fabric is buried to the correct depth and with the right amount of tension by the machine, which means you are not risking inspection failure and fines for non-compliance with environmental requirements.

- Working with a Small Team: What previously involved a team of four people, skidding a silt fence with a shovel and a hand trowel is now only attended by an operator and one helper securing the stakes.

The Concrete Slab Lifter (The Beak)

There is usually a lot of madness in demolition where destruction and removal alternate with each other, but the Concrete Slab Lifter, commonly referred to as “The Beak” or “The Monkey Fist,”, is one of the handful that brings a touch of elegance to demolition. The attachment comprises of a special jaw that goes under a slab and a clamp that is placed on a heavy and powerful moving and lifting lever. The slab is broken into sheets big enough for easy handling.

This is particularly useful for sidewalks, driveways, or foundation pads where you want to do a clean job of removing the material, avoid causing damage to the sub-base, and making no or little dust.

The main benefits of this tool in demolition projects located in cities are:

- Advanced Technology: The equipment moves very big slabs of concrete in one piece, thereby helping to speed up work at the place of loading and/or crushing when it is compared to pieces that are handled after demolition with breakers.

- Less Noise and Dust: By prying instead of hammering, there is a significant reduction of noise pollution and silica dust typically associated with the use of jackhammers.

- Sub-base Protection: You avoid churning up the dirt underneath because it lifts from the bottom, thus the next concrete pour may be made without additional preparation of the surface.

The Asphalt Cold Planer: Road Repair Specialist

Road milling is one of the greatest encounters of heavy road constructions in which huge lane machines are generally used, and the costs are sky-high. The main component of this attachment is a rotating drum with carbide teeth that scrape off asphalt or concrete surfaces at a specific depth.

With this unit, small contractors can participate in local authority road repair and parking lot maintenance act without any problem. The quantity and efficiency is such that a single operator with a Cold Planer can do a large road patching contract in a much shorter time than a crew with prior smaller equipment.

Firstly, it is more energy-efficient because less gasoline is consumed per square meter of application. Secondly, it is significantly less destructive (almost zero) to newly-laid surfaces and does not require additional protective measures. The Cold Planer achieves precision beyond the bucket’s capabilities.

- Mill Depth Control: The depth of cut can be precisely set thanks to skids that can be adjusted, thus just the damaged asphalt layer is removed without disturbing the base.

- Recycling Of Material: The milled material, also known as millings, may be recycled and used as a base material for other works; hence, less money is spent on disposal and materials.

- Multifunctional: It can also be used for removing traffic line paints and cutting transitions to new pavement for smooth driving surfaces.

The Stump Planer: Innovative Stump Removal

Somebody who has been in the business for a while might recall stump grinders – machines with a disc wheel operating at super high speed and scattering in a holly jolly manner dying woodland chips.

Here is a new and good-to-go skid steer attachment: just get the picture of a drill (screw) doing its job on a stump because it is a less stressful sister of a grinder in lower rpm but with incrementally higher torque. This attachment comes with a conical drill bit that has sharp screw-like threads and it carries out aggressive boring on a tree stump.

The drill core bit pulls itself deeper and deeper with wood shavings released being little and well confined. Due to a minimal safety risk, reduced noise, and few damages, this attachment can operate in locations that traditional stump grinders could not.

The great features of tool operation, safe and risk-free environment, and aesthetic value of the Stump Planer are reasonably complemented by other distinct benefits.

- Security Precautions Are Taken: The low-speed, high-torque mechanism reduces the risk of flying and therefore posing a threat to broken windows, vehicles, and people.

- Underground Stump Roots Are Removed: The drill taproot is destroyed to such an extent that resprouting is almost impossible thus, area clearing by replanting new vegetation is feasible.

- Mulching: The produced wood shavings are clean and well-contained thus collection for either mulch or disposal is an easy task that does not require a big cleanup effort.

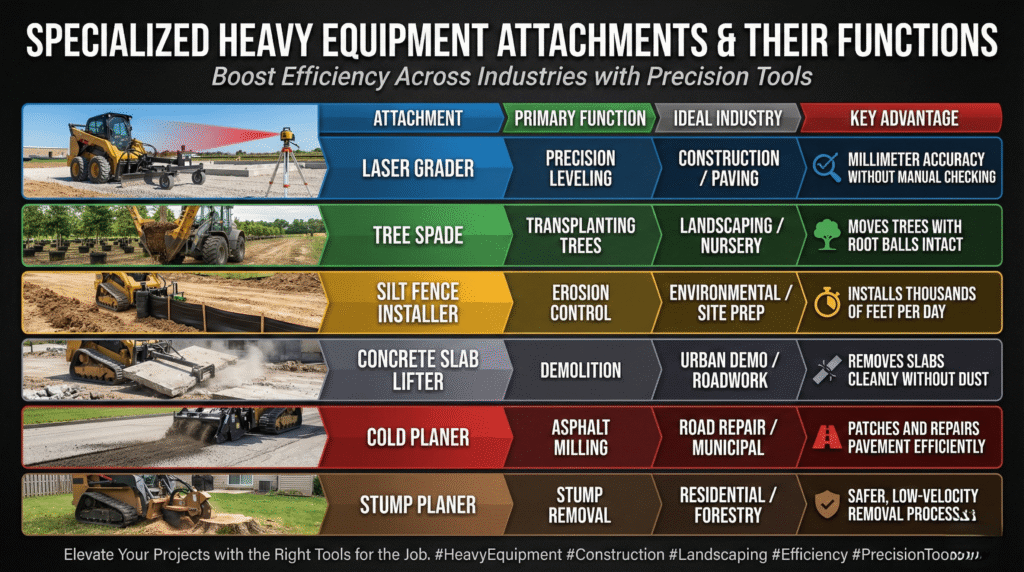

Table: Skid Steer Attachments

| Attachment | Primary Function | Ideal Industry | Key Advantage |

| Laser Grader | Precision Leveling | Construction / Paving | Millimeter accuracy without manual checking. |

| Tree Spade | Transplanting Trees | Landscaping / Nursery | Moves trees with root balls intact. |

| Silt Fence Installer | Erosion Control | Environmental / Site Prep | Installs thousands of feet per day. |

| Concrete Slab Lifter | Demolition | Urban Demo / Roadwork | Removes slabs cleanly without dust. |

| Cold Planer | Asphalt Milling | Road Repair / Municipal | Patches and repairs pavement efficiently. |

| Stump Planer | Stump Removal | Residential / Forestry | Safer, low-velocity removal process. |

Skid Steer Attachments FAQs

What is the difference between high-flow and standard-flow skid steer attachments?

Hydraulics with standard flow suffice for buckets, grapples, and regular augers. High-flow hydraulics provide more gallons per minute (GPM) as well as a higher pressure, which is the main requirement of the modern innovative skid steer attachments such as cold planers, huge snow blowers, and forestry mulchers, if they are to function properly.

Is it possible to use skid steer attachments on a compact track loader (CTL)?

You are right in thinking that most of the time you can. Usually, skid steers and compact track loaders are designed to use the same universal quick-attach plate. But, besides, one needs to make sure that his CTL has the hydraulic flow and weight capacity required to operate the specific attachment he is planning on using.

What are the most profitable skid steer attachments for 2025?

The highly profitable attachments are those that enable specialized services. They consist of forestry mulchers (land clearing), hydraulic breakers (demolition), and laser graders (precision site prep) since the operators of these tools can charge higher hourly rates than those performing standard bucket tasks.

Are skid steer attachments universal across all brands?

A majority of today’s skid steers use the “Universal Quick Attach” system (commonly referred to as Bob-Tach), thus making the plates compatible between the brands like Bobcat, Cat, and John Deere. Nevertheless, hydraulic couplers (hoses) may differ, and the use of high-flow attachments necessitates that specific machine capabilities are met.

How do I maintain my hydraulic skid steer attachments?

Keeping a regular check is imperative. Always run an inspection of hydraulic hoses to check for leaks or signs of wear, perform daily greasing of pivot points, look at wear parts (e.g., teeth or blades) to decide whether they are getting dull, and clean the attachment’s hydraulic couplers before hooking them up to the machine in order to avoid system contamination.

Do I need special certification to operate these innovative attachments?

Heavy machinery operator certification in general is only for the machine, and if you want to know the answer to whether you need a special certification in order to operate highly innovative attachments such as a tree spade or a cold planer, the answer is that you do in most cases. Manufacturers or rental dealers in most instances offer training courses for these complex tools.

Can a skid steer brush cutter cut down trees?

Yes, heavy-duty brush cutters (sometimes referred to as “mulchers”) can be used to cut down small trees. You can expect a regular brush cutter to take care of saplings with diameters of up to 3 inches, whereas a high-flow forestry mulcher can handle trees that are 6 or 8 inches in diameter.

Choose your Skid Steer Attachments

The world of skid steer attachments is decentralized, consisting of endless and ever-growing tool families. Consulting this comprehensive guide to innovative tools will reveal an unmatched ability to tackle jobs that previously would have required hiring specialized subcontractors or being out of reach altogether. From a Laser Grader capable of surgical precision to a Concrete Slab Lifter with brute force, these attachments prove that a skid steer is the ultimate transformer of the construction world. While you may be relying on ScissorLifts.org to get you up in the air safely, be sure to use the appropriate attachment with your ground equipment to achieve top efficiency and safety in the completion of your project.