Angle Brooms and Sweepers: Best Solutions for Neat Worksites

Keeping a construction, landscaping, or industrial maintenance site clean is a major safety and efficiency factor rather than just being nice to look at. Debris, mud, snow, and dust can be a source of hazards for the workers as well as the equipment so it is always better to prevent accidents and downtime by cleaning the site regularly. This is why high quality skid steer attachments including angle brooms and sweepers become a lifesaver. specially designed to address these problems directly.

At Skidsteerloader.org, we know that having the right tool really makes a difference, so here we have prepared you with a variety of angle brooms and sweepers that will help bond you and your cleaning work.

With these heavy-duty brooms and sweepers, you will achieve features that only few manual crews could: the conversion of your standard skid steer loader into a powerful cleaning machine capable of clearing vast areas in a fraction of the time.

No matter if you are a construction site manager, a municipality road maintenance specialist, or snow removal in a commercial parking lot, you have the performance and reliability that you need right here at Skidsteerloader.org to create and keep a sparkling clean environment.

The Power of Hydraulic Angle Brooms

The hydraulic angle broom is a vigorous skidsteer attachment for massive debris clearing in large, open areas. An angle broom unlike the normal type sweepers that gather up debris is constructed to sweep the material to the side so it can be used for clearing long pavements such as roads, driveways or parking lots.

The engine uses a high-torque hydraulic motor which turns the tightly packed,built-to-last bristles to the high speeds thereby breaking the dried mud, light snow and heavy gravel.Na Skidsteerloader.org the angle brooms have been fitted with the latest hydraulic angle systems which enable the operator to adjust the broom’s angle up to 30 degrees left or right, without stepping out of the cab.

Specifically, this function is used when the operation requires the material to be windrowed to the side of the road or when a path is to be cleared in situations where the machine can’t be easily re-positioned. The ruggedness of the frame makes the angle broom to be used even on rough grounds without sacrificing performance or stability thus no “bouncing” that results in an uneven sweeping pattern.

Featuring a direct-drive motor system, these brooms do away with the chains and sprockets, significantly reducing maintenance and increasing the lifespan of the attachment.

- Efficient Debris Handling: rapidly sending the dirt, snow and gravel to the side thus instantly creating clear paths without even the need for a second cleanup on the immediate path.

- Hydraulic Angling: allows 30 degrees of angle adjustment (left or right) so that operators can direct the debris wherever it is desired while remaining in the cab.

- Various Bristle Choices: come with poly wafers for general surface cleaning, wire wafers for penetrating hard compacted mud, or using a combination of both for the most versatile option.

Pickup Brooms: The Ultimate Clean-Up Solution

Where there is a need to completely get rid of debris as opposed to just pushing it to the side, Skidsteerloader.org is offering a Pickup Broom (Sweeper Bucket) which is a great choice.

These attachments offer a built-in collection bucket that will capture dust, dirt, and debris whilst you are sweeping. To get a perfect finish, the pickup broom traps tiny particles thus preventing them from becoming airborne, which is very important when working in a crowded place or a closed facility like a warehouse.

To enable the operator to work in the forwards or backwards direction, a cutting edge and a reversible bristle rotation are provided. It allows the bi-directional capability in scrubbing against curbs or walls to be the most efficient usage at a point where the brush hits the curb.

On top of that, many of our pickup broom models can be utilized with a water kit that sprays a mist during operation; this serves to reduce dust clouds and comply with environmental regulations while providing safe air for working conditions. When you get the attachment dump feature, you can directly lift and tip it in the container be it dumpster or truck thus the cleaning process is really simplified.

- Full Containment of Debris: includes a bucket that collects debris as it is being swept such that it is ideal for completely cleaning “zero-trace” in the most sensitive areas.

- Dust Management: with the ability of connecting a water sprinkling kit, flue silica dust can be suppressed and air quality at the job site can be maintained.

- Bi-Directional Cleaning: the operator can clean in both forward and reverse thus easier to clean tight corners and flush against curbs.

Features of Skid Steer Angle Brooms and Sweepers

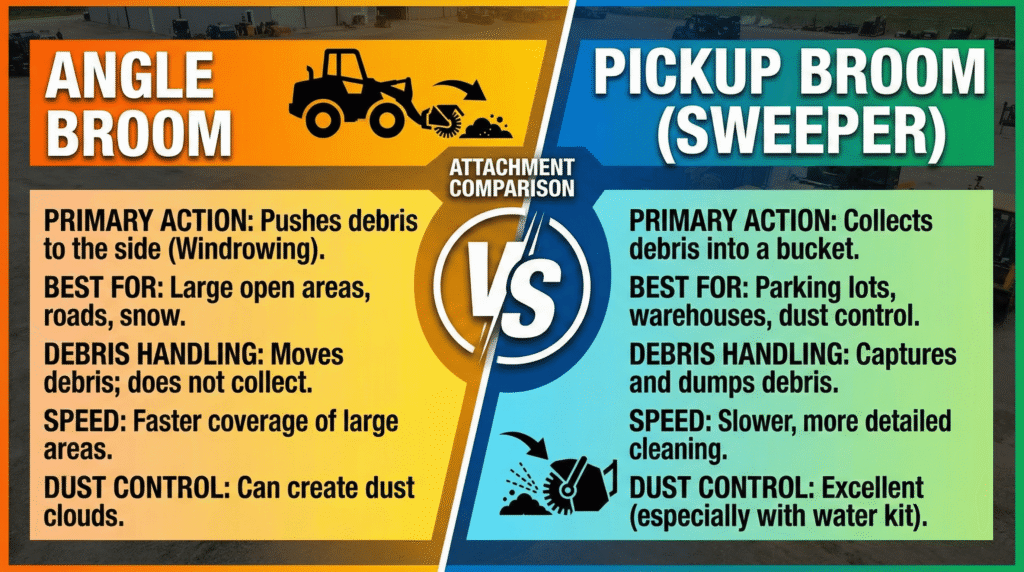

Angle Brooms vs. Pickup Brooms Compared

The decision to get one of the two mainly depends on the task that the site of your project is bursting with. While both consume the hydraulic power of your skid steer to give the best results, their uses are totally different.

When an angle broom is added to the maximum, the most significant method will be that the area is totally cleared and accept that the debris possibly pushed out on the shoulder of the road, or a remote driveway, for it is the road clearing that an angle broom simply came to be the most efficient.

Using a pickup broom is a must in situations where you can’t just sweep the debris on the curb e.g. in the city centre or a finished parking lot; you have to collect and dispose of the trash. Knowing the differences of these 2 is the key to selecting the right option from Skidsteerloader.org.

The functionality and application of angle and pickup brooms have been broken down here to help you choose.

Table: Angle Brooms and Sweepers

| Feature | Angle Broom | Pickup Broom (Sweeper) |

| Primary Action | Pushes debris to the side (Windrowing) | Collects debris into a bucket |

| Best For | Large open areas, roads, snow | Parking lots, warehouses, dust control |

| Debris Handling | Moves debris; does not collect | Captures and dumps debris |

| Speed | Faster coverage of large areas | Slower, more detailed cleaning |

| Dust Control | Can create dust clouds | Excellent (especially with water kit) |

- Use-Case: Angle brooms are mainly used for road construction and snow removal while pickup brooms are the standard equipment for street cleaning and warehouse maintenance.

- Operational Speed: Angle brooms usually permit higher speeds while a worker with a pickup broom has to slow down so that the bucket will not miss any of the material.

- Site Constraints: Pickup brooms function in limited areas where the space is very tight and hence the operator cannot push the debris whilst angle brooms need an open area for windrowing.

Key Features of Skidsteerloader.org Stock

Looking through the lineup of brooms and sweepers at Skidsteerloader.org, it is clear that we emphasize sturdiness and performance as the most important features of our products.

Our attachments have frames made of top-quality steel that have been handcrafted to endure daily wear from construction sites. One of the crucial elements which we cannot ignore is how well the bristle wafer system is maintained and controlled. We have convoluted bristle wafers which offer a “flick” action that is unmatched by normal straight bristles.

this has the effect of barely letting dirt get away from the crevices and cracks on pavements. Moreover, adjustable height controls are incorporated into our brooms which is the key to a longer usage of your bristles. Height setting done inappropriately is the number one cause of wear way too early; if the broom is pressed too hard against the ground, the bristles mop rather than flick, reducing efficiency.

Our machines feature floating linkages that follow the terrain thus maintaining constant contact even with surfaces like gravel roads or cracked asphalt which are not even.

- Floating Linkage System: detaches the loader arms from the broom head so that the broom head can follow the ground, avoiding missed spots and uneven bristle wear.

- Direct Drive Motors: with no need for chains and sprockets, these motors give maximum torque by providing hydraulic power to the bristle core.

- Quick-Change Core: facilitates easy patch up thereby enabling the operators to do the in-field replacement of worn bristle wafers without the need for special tools or loss of time.

Applications in Various Industries

The brooms and sweepers that are up for sale at Skidsteerloader.org are as versatile as they come. They bring extra value all year round in the operations across numerous industries. In utmost construction, mud and other soils tracked to public roads are kept at bay by these machines thus the first point of contact for track-out material with public roads are these attachments.

Landscaping companies breathe a sigh of relief when they find such a perfect product as angle brooms for dethatching vast lawns or for leaf and pine needle collection in big properties. During winter, these attachments become real snow removal heroes. When the snow is less than 6 inches, an angle broom is usually more effective than the plow because the surface is left clean without any damage.(for example, the lane markings are not erased deeper).

Therefore, property managers that are responsible for maintaining the safety of pedestrians and vehicles in shopping centers and apartment complexes often speak highly of such tools.

- Construction & Demolition: perfect for clearing a construction site, getting rid of the dangerous materials like glass and nails, and preventing mud from being tracked onto the roads.

- Winter Maintenance: clearing sidewalks and other paths of snow and slush in places where the usage of plows can be harmful or too aggressive.

- Agricultural Applications: utilized in barns and feedlots for picking up feed, cleaning alleys, and handling bedding materials efficiently without the need for manual labor.

Maintenance Tips for Long-Lasting Performance

For getting maximum utility and value from your purchase at Skidsteerloader.org, you must have an excellent maintenance program in place for your broom attachment. Bristle life depends greatly on the operator’s machine handling.

The attentive operators know well the scenario that very high down-pressure will bend the bristles thus making them to wear out fast. In fact, the bristle tips should flick the surface with only 2 to 4 inches of contact area. Besides, it is also important to frequently check the hydraulic hoses and couplers; a tiny leak can result in a pressure drop and hence a reduction in the sweeping power.

Another recommendation we make is to rotate your bristles if you see uneven wear patterns which may be caused by constantly sweeping in one direction or on a sloped road. Lubricating the pivot points and bearings should be part of your pre-operation checklist to avoid mechanical failure and to ensure smooth running of the equipment.

- Right Down-Pressure: make sure that the broom pattern on the floor is between 2 and 4 inches (about 5 to 10 cm). Excessive pressure results in “mopping” which damages the bristles at a really fast rate.

- Storage Habits: keep the broom always on its parking stands and never put it down on the bristles for they will get deformed permanently and the broom will lose its action of sweeping.

- Hydraulic Backbone: examine the hydraulic hoses regularly for signs of wear and leakage and match the pressure of your skid steer with hydraulic motor specs of the broom for the optimum results.

Why choose Skidsteerloader.org?

At Skidsteerloader.org, the attachments are not just a product on the shelves; they are a final word in the solutions for cleanliness, safety, and productivity of the worksites. It is okay to understand that downtime equals money and that is why our attachments come ready to ship and are easy to install.

All our angle broom and sweepers are got universal quick-attach mounting system hence compatible with all major skid steer brands. Choosing an attachment from us you get a field-tested product that has returned the results in the harshest conditions. Besides, we are here for you always with our pool of experts who guide you in selecting the proper motor package and hydraulic flow matching width for your machines.

What we stand for is transparency and quality whereby every product description on our site is a true reflection of a tool’s capability; hence you know what you are purchasing.

- Universal Compatibility: the quick-attach plates on our attachments are of the industry-standard type, allowing them to be easily fitted to major loader brands such as Bobcat, Cat, and Kubota.

- Expert Support: speak to our knowledgeable support team, who can help you match your machine’s hydraulic flow (GPM) to the right broom motor for the best performance.

- Heavy-Duty Guarantee: these attachments are manufactured with reinforced steel hoods and high-quality hydraulic components that ensure their durability for years to come.

FAQs – Skid Steer Angle Brooms and Sweepers

What is the difference between a skid steer angle broom and a pickup broom?

An angle broom is used for pushing the debris to the side (windrowing) and is ideal for open locations like roads. A pickup broom (or sweeper) comes with a bucket that collects the debris, thus makes it suitable for parking lot and areas where the trash needs to be taken away.

Can I use a skid steer angle broom for snow removal?

Angle brooms are definitely a great choice for removing light snow (generally less than 6 inches). They do a better job of cleaning down to the pavement as compared to a plow and there’s less chance of them damaging surface markings or pavers.

How do I choose the right width for my skid steer broom?

You will find it beneficial to acquire a broom which is definitely wider than the tires or tracks that your skid steer is using at the time when the broom is fully angled. A 72-inch or 84-inch broom is the most commonly recommended size for the typical standard skid steer so as to avoid running over the debris that you are trying to gather.

How often should I replace the bristles on my skid steer sweeper?

Replacements of the bristles should occur when the length is only about half of the original one or when the flicking action is completely lost. Typically the life-span of the bristles is between 100 and 200 hours of use although it may vary depending on surface abrasiveness and applied down-pressure.

Do I need high-flow hydraulics to run a sweeper attachment?

Not really. A huge majority of angle brooms and pickup sweepers function very well on standard-flow hydraulics (typically 10-25 GPM). However, it is very important that you check your machine’s flow rate against the attachment’s requirements in order to avoid motor failure.

How can I control dust while using a skid steer broom?

The water sprinkler kit is a broom attachment which is also the best and easiest way to avoid dust generation while you are working. Many of the pickup brooms from Skidsteerloader.org have water tanks and spraying nozzles which help in reducing the dust level by dampening the debris before it is swept, thereby reducing dust in the air significantly.

Why is my skid steer broom wearing out unevenly?

The most usual explanation for uneven wear is that down-pressure was not properly adjusted or the broom head was misaligned. If the broom is not perfectly level with the ground, then the side with the lower position will wear much faster. Always make use of the floating linkage setting and verify your tyre pressure so that the machine will remain at a level.