High-Flow vs. Standard-Flow Skid Steer: The Ultimate Hydraulic Guide

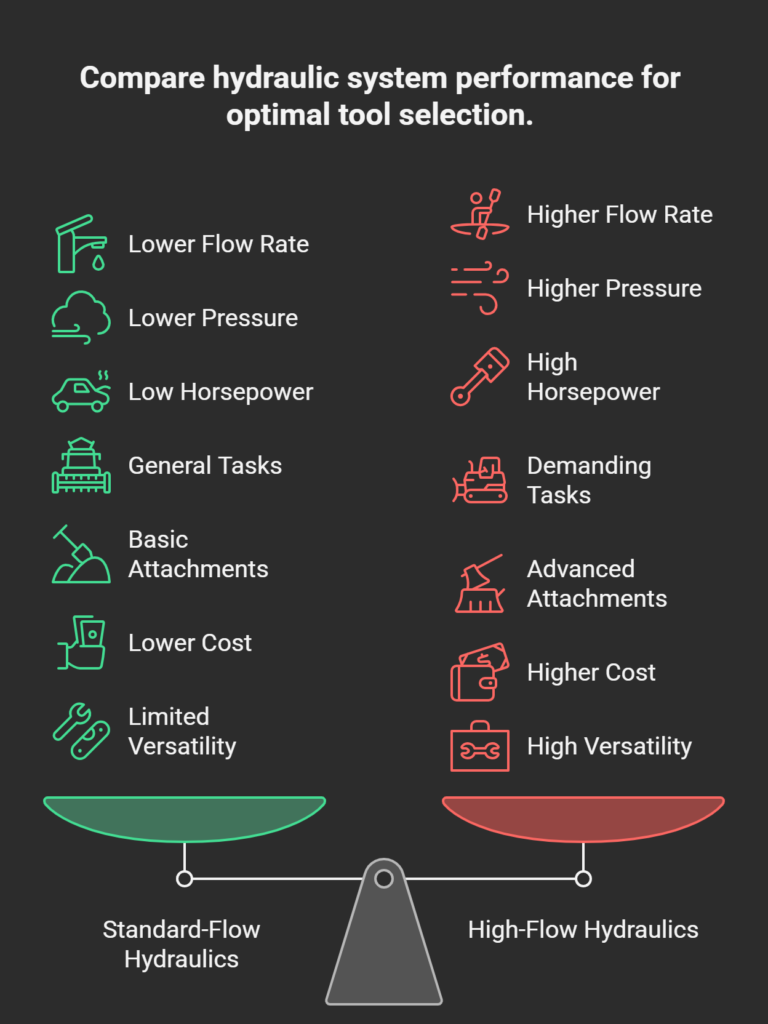

What should be the hydraulic flow rate for the skid steer? And what attachments will it use? These questions may bring you a lot of confusion while you are shopping a skid steer loader. The manufacturers make the most powerful models, such as the TYPHON line, but beyond simply choosing the brand or lift capacity, you have to decide if you want a High-Flow Vs. Standard-Flow Skid Steer.

This decision is not about just getting more “horsepower” for the sake of it; it is about ensuring that the hydraulic power of your machine meets the requirements of the specific attachments you plan on using. If you choose the wrong alternative, you might get a machine that is too weak to operate your expensive forestry mulcher, or you might end up spending more money on a high-flow system when a standard one would be enough for your bucket and pallet fork.

Hydraulic flow rate is the measure of liquid volume coming through the pipe in Gallons Per Minute (GPM) and understanding it is a key to unlocking more value from your investment. Your skid steer’s hydraulic system is like the circulatory system of your body: it supplies the lift arms with pressurized fluid, and it is especially the auxiliary circuit that controls your attachments.

High flow, which is the performance upgrade for extreme work, is not a standard configuration. In this article, we will analyze the technical details, attachment compatibility, and performance characteristics of both flow systems so that you can better pick the suitable machine for a construction site, landscaping, or forestry work.

Understanding Hydraulic Flow: GPM and PSI Explained

The reason for the debate between High-Flow vs. Standard-Flow Skid Steer starts with understanding how Flow (GPM) together with Pressure (PSI) correspond. Consider hydraulic flow as a stream of water: to keep it simple let’s say GPM is the amount of water flowing down the stream, while PSI (Pounds Per Square Inch) is the force or speed of that water hitting an object.

Standard-flow systems generally produce between 17 and 24 GPM with pressures in the range of 3,000 to 3,500 PSI. For general construction tasks, this setup is more than enough to provide hydraulic horsepower to the working components. It is the “standard” because it generally serves the needs of about 90% of skid steer operators who mainly use the machine for earthmoving, material handling, and light excavation tasks.

However, stepping up to a high-flow system means a significant volume increase, usually hovering around 30 to 45 GPM, and in some cases, the pressure level occurs to be similar to standard flow. The larger volume of fluid causes much greater Hydraulic Horsepower. This parameter – Hydraulic HP – reflects a machine’s potential power to do work. The equation (Flow x Pressure / 1,714) demonstrates that even if the pressure stays the same, doubling the flow from 20 GPM to 40 GPM provides double the hydraulic power to the attachment.

This explains why high-flow machines are not only “faster” they are more capable of operating under heavy loads for a longer time at a high torque level without the attachment stalling or the hydraulic fluid overheating.

- Standard Flow characteristics: Mainly provides 17–24 GPM; suitable for “static”, or slow-moving attachments.

- High Flow characteristics: Provides 30–45 GPM; made for high-speed, continuous rotation attachments.

- The Power Equation: High flow delivers the necessary hydraulic horsepower to keep the motor running when working against heavy materials like asphalt or thick timber.

The Attachment Factor: What Requires High Flow?

The quantity and nature of attachments in your inventory is the very first thing that will compel you to go for a high-flow vs. standard-flow skid steer. Machines with standard flow have great versatility and can be used with most tools.

A standard-flow model is sufficient if your main attachments are buckets, grapples, pallet forks, or hydraulic breakers. Even a few rotating attachments, such as standard-duty augers (for dirt) and trenchers (for loose soil), could work effectively at standard flow.

These types of tools depend more on the mechanical advantage of the machine’s lift or an intermittent hydraulic pressure rather than a continuously flowing, high-volume stream of fluid.

On the other hand, high-flow hydraulics are essential for so-called “power-hungry” attachments that need to be run at high speed with a continuous high-speed rotation. Suppose you are using a cold planer for asphalt that has to run the drum lined with carbide teeth at a sufficiently high speed so that it grinds the pavement while the tool is pushed forward.

The moment the teeth come into contact with the road surface, a standard-flow system fails because the motor stalls. At the same time, forestry mulchers depend on an enormous energy supply to instantaneously convert trees into wood chips.

If you want to use a mulcher requiring a high-flow hydraulic system with a skid steer that has a standard flow, then you must be aware of the fact that the performance is going to be very poor; the drum will rotate very slowly, there will be frequent jamming, and you will be risking damage to both the attachment and the loader’s hydraulic pump because of the backpressure and overheating problem.

- Standard-Flow Capable: 4-in-1 Buckets, Grapples, Hydraulic Hammers, Standard Augers, Trenchers.

- High-Flow Needed: Cold Planers (Asphalt millers), Forestry Mulchers, Stump Grinders, Heavy-Duty Snow Blowers.

- If You Mismatch: Trying a high-flow attachment on a standard machine will result in low operational efficiency, frequent stalling, and potential damage to the hydraulic system.

Comparing Operational Costs and Efficiency

One major parameter in the High-Flow vs. Standard-Flow Skid Steer equation is the cost variable, both from the initial purchase and the operational perspective. When buying a new machine, a high-flow package is a pricey option and one that typically raises the purchase price by several thousands of dollars.

The reason lies with larger hydraulic pumps, wider-diameter hoses, and greater cooling capacity needed to dissipate heat generated by such high fluid volumes. Nevertheless, you should offset this initial investment against your productivity gains. If you are a vegetation management contractor and rent a high-flow machine for a month, the rent charges may be nearly equal to the price of upgrading the machine.

By having this tool at your disposal, you can bid on jobs that are out of reach for competitors running standard machines—jobs that would be much more remunerative, such as land clearing and road milling.

However, another factor to think about among High-Flow vs. Standard-Flow Skid Steer is fuel consumption. When machines equipped with high-flow capability operate attachments which require hydraulic fluid at high flow rate, they consume more fuel. To be able to power the bigger hydraulic pumps at maximum capacity, the engine must work harder thus using more fuel.

On the other side, if you purchase a high-flow machine but only use a bucket, you will probably simply waste a bit more fuel while at the same time being burdened with heavy components that have no operational benefit. Another point worth mentioning here is that high-flow machines are often equipped with the possibility for “standard flow” mode for the running of regular attachments, thus allowing for dual functionality.

In contrast, converting a standard-flow machine to high flow, without a very expensive and intricate aftermarket mod, is simply out of the question. Which is usually not even cost-effective to compare with buying the correct machine from the start.

- Initial Investment: The higher initial cost of high-flow systems is mainly due to the use of upgraded pumps, couplers, and cooling systems.

- Fuel Usage: Operating high-flow attachments at full capacity requires more fuel, which eventually translates into larger daily operating expenses.

- Expected Market Price: High-flow skid steers typically retain more value on the resale market because they have a wider potential customer base among specialized contractors.

Performance Comparison Table: High-Flow vs. Standard-Flow Skid Steer

| Feature | Standard-Flow Hydraulics | High-Flow Hydraulics |

| Flow Rate (GPM) | 17 – 24 GPM | 30 – 45 GPM |

| Typical Pressure (PSI) | 3,000 – 3,500 PSI | 3,000 – 4,000+ PSI |

| Hydraulic Horsepower | Low to Medium | High to Very High |

| Primary Use Case | Earthmoving, Lifting, Digging | Demolition, Forestry, Snow Removal |

| Ideal Attachments | Buckets, Grapples, Breakers | Mulchers, Planers, Rock Saws |

| Cost | Lower Purchase & Operating Cost | Higher Purchase & Fuel Cost |

| Versatility | Limited to general tasks | Can run both High & Standard tools |

FAQs on High-Flow vs. Standard-Flow Skid Steer

What is the GPM difference between standard and high flow?

A flow of 17 to 24 Gallons Per Minute (GPM) is what is typically seen with standard flow skid steers. A high-flow system will have at least 30 GPM and may go to 45 GPM or further at the super-flow models. So it is this difference in volume that gives the additional hydraulic horsepower necessary for the heavy-duty attachments.

Can I run a high-flow attachment on a standard-flow skid steer?

That’s possible if the connectors of the couplers are the same, but don’t do it anyway. What will happen is that the attachment will function poorly, the rotation speed will be so low that it will lack efficiency, and at the slightest load it will stall. To make the matters worse, your hydraulic system may overheat and you will have to face a very costly repair of the worn out components.

Does high flow mean more lifting power?

No, not at all. High flow is all about the auxiliary hydraulic circuit powering the attachments. Neither the loader arm’s raising power nor the bucket’s breakout force get affected by it. Typically, for the same model size, a high-flow and a standard-flow machine have a tipping load and a lift capacity that are only marginally different from each other if at all.

Is high flow worth the extra money?

It only pays off if you are actually going to use high-flow attachments. If your work is limited to earthmoving, loading trucks, and basic site cleanup, you are over-spending. But, if you want to keep your options open and possibly expand into land clearing (mulching) or road repair (milling) in the future, making that investment may be a wise decision for your fleet’s longevity.

How do I know if my skid steer is high flow?

You can identify a high-flow model by the hydraulic couplers present on the loader arm. Typically, three hydraulic couplers (one pressure, one return, and one case drain) or a separate larger coupler block can be seen on high-flow machines. Another option is to search for a “High Flow” sticker on the boom or check the button layout inside the cabin, where there should be a distinct toggle to switch to high-flow mode.

Does high flow use more fuel?

Yes, when the high-flow mode is activated. It takes quite a bit of engine horsepower to supply 40+ gallons of fluid continuously and thus more fuel is burnt. On the other hand, when operating in standard mode (e.g. simply using a bucket), a high-flow machine will have about the same fuel consumption as a standard machine with a similar engine capacity.

Can I add high flow to a standard skid steer later?

Though aftermarket kits are there, they cost a fortune and are a real pain in the neck to carry out. Besides changing the hydraulic pumps, valves, hoses, you will most likely be adding a cooler. Usually, it is financially more advantageous to replace your conventional machine with a high flow model rather than trying a conversion.

Final Decision – High-Flow vs. Standard-Flow Skid Steer

Choosing between a High-Flow vs. Standard-Flow Skid Steer is a tactical move that depends on your present and potential uses. For general landscaping, material handling, and light construction tasks, a machine with standard flow would be the best power and economy combination.

Whereas for the scenarios where your attachments are particularly aggressive, be it mulchers or cold planers, in that case the very issue of the high-flow system arises: you can’t achieve work efficiency without one. There are numerous brands on the market, like the TYPHON range, which make reliable machinery, regardless of flow category, so you do not have to compromise quality while seeking a machine just fitting your need.

In addition, you should always confirm the GPM requirements of your attachments prior to connecting them for both safety and excellent performance among High-Flow vs. Standard-Flow Skid Steer.