Hydraulic Attachments vs. Non-Hydraulic Attachments: Which Skid Steer Should Use?

The skid steer loader is one of the most versatile tools in the construction, landscaping, and farming industries. The main reason for its productivity is the ability to change it quickly by the various attachments, into the specialized equipment that is needed. Let’s dive into today’s topic Hydraulic Attachments vs. Non-Hydraulic Attachments: Find out which skid steer offers the ultimate versatility and strength for your tasks!

Yet, the selection of the correct skid steer attachments—determining whether to use hydraulic attachments or non-hydraulic attachments—is a very significant business and technical decision. Your operational efficiency, the amount of work you can do, and your total return on investment (ROI) are all affected by this decision.

If you disregard the technical specifications of your machine and the work, it can result in expensive downtime or insufficient performance. This detailed guide differentiates these two categories of attachments so that you can choose the best for your fleet and your profit account.

The Technical Core: Understanding Skid Steer Hydraulics

The source of power for high-tech tools is the machine’s auxiliary hydraulics. The system that gives the pressurized fluid is the one that enables movement, force, and power to the output of the machine for the external accessories. Getting to know this system is an absolute must.

The performance of any powered tool is judged by how much fluid is used per unit time, i.e. flow (Gallons Per Minute or GPM) and how much the device is loaded per unit area, i.e. pressure(Pounds per Square Inch or PSI)

- Flow(GPM)determines the speed at which the attachment operates (e.g., how fast an auger spins).

- Pressure(PSI)dictates the force or torque the attachment can generate (e.g.,the force a breaker hits with).

Inadequate matching of the attachment’s needs to the machine’s supply can greatly reduce performance, thus the tool may operate at a slower speed, or it may even cause damage to the system.

There are two main categories to which the hydraulic capacity of skid steers is divided: Standard Flow and High Flow.

- Standard Flow systems normally deliver 18 to 25 GPM. They can be used for light- to medium-duty tools.

- Standard Flow is a great energy saver and is capable of performing the majority of everyday tasks, such as small trenchers, standard augers, and light powered brooms.

- By High Flow one means a system that has a minimum of 30 GPM and sometimes even more. These systems not only have a separate pump but also need heavy-duty cooling parts.

- High Flow is the extreme case that requires the most powerful and energy-greedy hydraulic machines such as a forestry mulchers, big cold planers and heavy-duty rock saws.

- By buying a high-flow skid steer, you can very well open the door to many more heavy-duty and expensive types of work that you can do with your skid steer.

While purchasing hydraulic attachments, it is imperative to follow the manufacturer’s GPM and PSI specifications rigorously. Although physically the attachment might be connected, insufficient flow will turn a high -performance tool into a severely underpowered and inefficient one.

On the other hand, if you use an attachment which requires a flow rate that is much higher than your machine’s capacity, it could result in hydraulic fluid overheating and the pump and seals wearing out prematurely.

At the same time, to keep a powered tool in good working condition, it is essential that even the small parts—fluid, filters, and quick couplers—are in perfect shape.

Non-Hydraulic Attachments: Reliability and Low Cost

Non-hydraulic attachments are the basic, unpowered tools that any skid steer attachments fleet cannot do without. These devices are fully dependent on the machine’s standard lift, tilt, and drive movements to work.

Such instruments are the accessories that perform the most common tasks like general-purpose buckets, specially designed pallet forks, and grading attachments. Due to their inherent simplicity, they possess crucial operational advantages.

The decision to buy non-hydraulic attachments is often driven by reliability and cost.

- Mostly Reliable: The most common decision is to invest in non-hydraulic tools due to their long-term reliability and low cost.

- Lower Initial Investment: Because they do not have motors, hoses, and complex components, the purchase price is quite a bit lower compared to their hydraulic counterparts.

- Minimal Maintenance: Maintenance is mainly structural, which involves checking welds, replacing teeth, and fixing wear plates; hence, the ownership costs are very low in the long run.

- Less Machine Strain: They do not require energy from the auxiliary hydraulic system and, thus, heat production is at the minimum, fuel consumption is likewise reduced compared to that when an auxiliary pump is running, and wear and tear are separators are among the benefits that can be achieved by means of non-hydraulic attachments.

On the other hand, the simplicity of these tools restricts their abilities to only non-powered activities.

- They are the perfect ones for handling simple earthworks, carrying, and dumping.

- They are not capable of carrying out any task that requires mechanized movement to be continuous, e.g., chipping, grinding, or high-speed sweeping.

- Reliance on these tools for high-volume or specialized tasks results in inefficiency, which, in turn, leads to increased labor costs and longer project timelines.

Non-hydraulic attachments will still be the most economical and reliable option for businesses whose operations are mainly focused on earthmoving, demolition cleanup, and material staging.

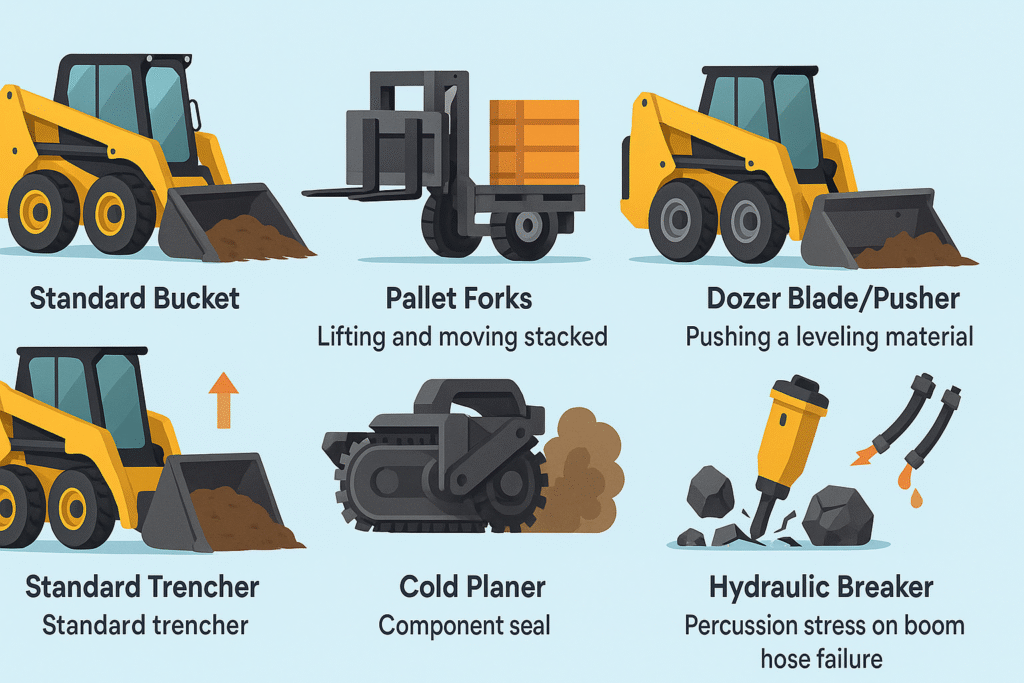

| Non-Hydraulic Attachment | Primary Function | Maintenance Focus |

| Standard Bucket | Digging, loading, transporting | Wear plates, cutting edge, structural welds |

| Pallet Forks | Lifting and moving stacked goods | Tine straightness, mounting plate integrity |

| Dozer Blade/Pusher | Pushing and leveling material | Blade edge replacement, tilt cylinder pins |

Hydraulic Attachments: Power, Precision, and Expanded Scope

Hydraulic attachments make a skid steer loader a hi-tech, multi-functional unit that can complete special tasks which it used to be the job of large, single-purpose machines. These are high-efficiency instruments designed for continuous, automated work.

The examples are from augers and trenchers to complicated mulchers and planers, all of which get their power from the continuous flow of pressurized hydraulic fluid.

The advantages of hydraulic attachments revolve around productivity and capability.

- Incomparable Versatility: They bring in the possibility of doing such things as site prep (mulching), installation of utilities (trenching), and working with concrete (breaking/planing).

- Maximum Efficiency: The dramatic shortening of the project period and the staff-intensity thus being very low are the main reasons why the users of this type of labor-saving devices get a strong return on their investment (ROI).

- Accuracy: For example, hydraulic trenchers allow for consistent and uniform results that are impossible to achieve with non-powered methods.

Such a high performance, however, also means that there are some operational and cost considerations that follow.

- Increased Upfront Cost: The presence of costly hydraulic motors, seals, and precision components is what causes the initial purchase price to be substantially higher.

- Complexity and Intolerance: Hydraulic motors are extremely sensitive to contamination and thus require specialized maintenance and technical skills for repair.

- Machine Demand: To achieve high RPMs and thus GPM flow the skid steer has to be run at high RPMs thus leading to increased fuel consumption and causing various thermal and mechanical stresses on the machine’s systems apart from that energy use is increased.

Such an investment is very valuable to utility contractors, for instance, or concrete repair specialists, as well as land clearers whose main business involves them.

| Hydraulic Attachment | Minimum Flow Requirement | Key Operational Risk |

| Standard Trencher | Standard Flow (20-25 GPM) | Overheating, chain and sprocket wear |

| Cold Planer | High Flow (30+ GPM) | Component seal failure, dust contamination |

| Hydraulic Breaker | Standard Flow | Percussion stress on the boom, hose failure |

The Deciding Factors : Matching Tool to Task

Hydraulic Attachments Vs Non-Hydraulic Attachments:

The final choice between hydraulic vs. non-hydraulic attachments should be a well-thought-out plan decision based on three pillars: the technical specifications of the machine, the monetary situation, and the frequents of job site demands.

Machine Capacity Check

Before buying an accessory, make sure to check out the limitations of your skid steer.

- Rated Operating Capacity (ROC): Your machine should be able to handle, without a problem, the combined weight of the attachment and the material that is to be processed.

- Auxiliary Flow Output: Don’t just take the machine label for granted. It’s factory tested, but it’s still worth checking the actual GPM and PSI of the machine. If an error can be made, it is a very big mistake of high flowing Standard machines and simply bad performance and frustrations is the result of this.

While an over-spec’d tool will hardly be able to perform to its full potential, a high-spec’d machine (only High Flow used for simple tasks) represents an unnecessary initial investment premium.

Budgetary Constraints and ROI

The purchase should be backed by financial justification which is clear and measurable.

- The non-hydraulic attachments are the ones that load the quick money return on investment account with their low-to-no-cost feature. Also, they can be considered the most profitable ones, especially in the run of everyday tasks, as they can provide an immediate payback.

- For hydraulic attachments there is a necessity to perform a full-blown cost analysis carefully: take into account the initial expense and the maintenance together and compare that with the renting, the manual labor, and the cost of doing the job yourself.

- If the high price of a powered tool is the only grounds for its existence, then it must be frequently employed in order to displace high labor expenses or in situations where it enables high-margin specialized services.

Job Site Demands and Business Focus

The types of activity that form the core of your business should be the ones that dictate the composition of your attachment fleet.

Property maintenance such as routine sweeping, snow removal, and light grading which is most likely to be the business focus of you will be working with a small selection of standard-flow hydraulic tools complemented by a robust set of non-hydraulic attachments, thus being served the best.

- On the contrary, a company that concentrates on tough demolition, stump grinding, or large-scale utility installation will be requiring heavy investment in high-flow, off-road-capable, hydraulic attachments to achieve the productivity goals.

- Make use of an attachment selection guide to rank tools basing on the weighted frequency and profitability of each task category in your annual schedule.

Maintenance, Efficiency, and Operational Contrast

Besides the operational differences, the two attachment types also differ in terms of maintenance and fuel efficiency.

Maintenance Routines

Non-hydraulic attachments are of simple and predictable nature when it comes to maintenance.

- Work is mainly concentrated on maintaining the structural condition: continuous checking for stress cracks and changing those parts like teeth and cutting edges that are bolted on and worn by the use.

- Most of the servicing can be done by the company staff, thus there is a saving on the operational overhead.

Hydraulic attachments are of a demanding nature, both in terms of care and rigor.

- Work is concentrated on the fluid: checking seals, hoses, and, very importantly, ensuring that quick couplers are clean before connecting them so that there is no contamination.

- At the same time, they impose an increased demand for fluid and filter changes on the skid steer, which should be done more frequently if high-flow tools producing a lot of heat are used.

- If the specialized maintenance is neglected, it will often result in an expensive hydraulic motor failure and thus, it will be necessary to employ labor of a certified technician.

Fuel Efficiency

- There is a distinct difference in operational expenditures linked to power consumption.

- Non-hydraulic attachments are naturally fuel-friendly as the engine powers only the main lift and tilt functions.

Hydraulic attachments require the engine to run at higher RPMs to ensure sufficient GPM flow, thereby, fuel consumption is increased and, the engine and cooling system are subjected to a greater wear and tear. Also, this has to be taken into consideration when calculating the total cost of ownership (TCO).

Frequently Asked Questions (FAQ)—Hydraulic Attachments vs. Non-Hydraulic Attachments

What is the most important factor to determine whether or not I require a high-flow skid steer?

The most important factor is the amount of GPM needed for the performance of the task that involves high power and speed such as heavy forestry mulching or cold planning. In case your work requires either high rotational speed or very high cutting force, then High Flow is necessary.

Is it safe for me to operate a Standard Flow attachment on a High Flow machine?

The answer is yes to most of the hydraulic Standard Flow devices, they can be a High Flow machine safely operated. The flow control system of the machine will generally adjust the oil volume to the demand of the attachment, nevertheless, the performance will not go beyond the limit set by the attachment’s design.

Why do some hydraulic attachments have to be equipped with a case drain line?

The case drain line (the third hose) is a must for high-performance motors. It gets rid of the internal pressure and excessive heat from the motor housing directly to the tank, thus, avoiding the buildup that could, otherwise, explode the motor’s shaft seal.

How often do I need to change the hydraulic fluid if I am using demanding attachments?

The fluid and filters should be checked more frequently and changed more often, than the machine’s standard service intervals, if it is running on heat-generating hydraulic attachments. Contamination should be kept at bay, as it is the number one enemy of hydraulic components.

Is it better to purchase a mid-range machine together with high-end attachments or a high-end machine with mid-range attachments?

Normally, it is more sound to give priority to a machine with sufficient hydraulic flow capacity (high-end machine) that is able to properly power the specialized attachments. No matter how great the attachment is, if it is underpowered, it will never perform properly.

Do non-hydraulic attachments warm up in any way? Are constituents besides wear parts responsible for the ongoing costs?

The major ongoing expenses are very minimal: the eventual substitution of wear parts (such as edges and teeth) and the necessary structural upkeep to prevent rust and welding failure. There are no associated fluid or filter charges.

What am I supposed to do if my hydraulic attachment is slowly working even though the machine is capable?

The very first thing to do when your hydraulic attachment seems to be running slow while on a capable machine is to check if the quick couplers are properly connected and clean. Then, look at the hydraulic fluid: is there enough of it? Is it at the right temperature? If it is low and/or the machine is overheating, this will trigger it automatically lowering the flow in order to protect the system.

Technical Hydraulic Attachments Vs Non-Hydraulic Attachments Statistic Decision:

The choice of skid steer attachments is a tactical decision which determines the working capabilities of your equipment. Non-hydraulic attachments offer a good level of reliability and are inexpensive for basic material handling operations. Hydraulic attachments give the necessary power and accuracy a single can be required for a high-value, complex job.

Top operators wisely keep a mixture of both types in their arsenal, thus their machines being not only a perfect match in terms of capabilities but also meeting the financial requirements of their main business. By using the right tool for the right job, you ensure the highest possible efficiency, safety, and profitability of your skid steer loader.