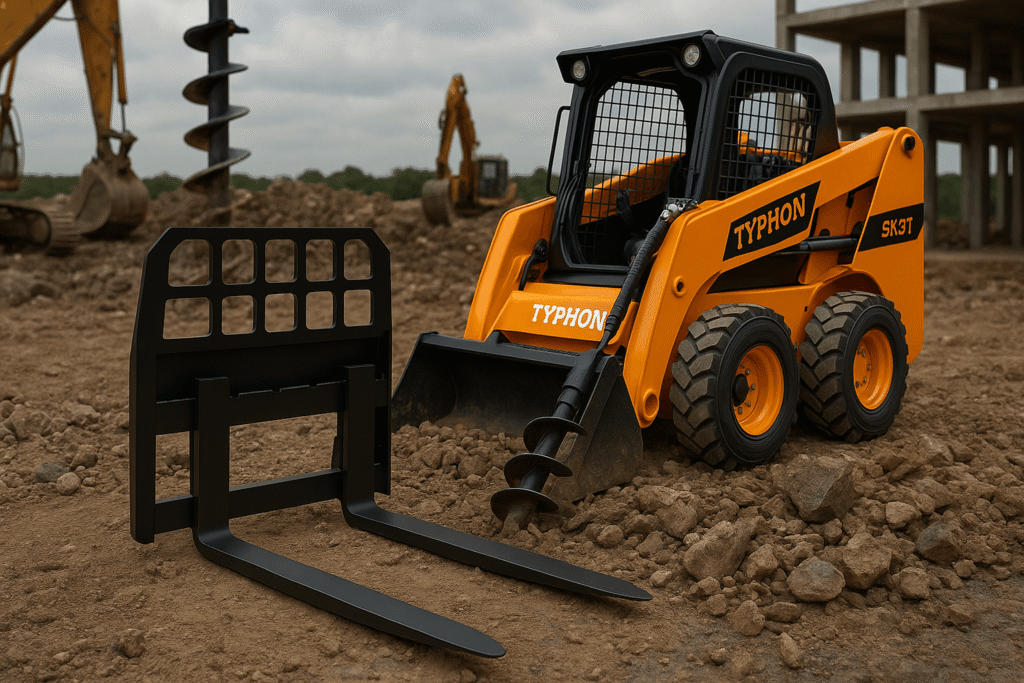

Skid Steer Loader Hammer Maintenance Manual

Keeping a skid steer loader hydraulic hammer attachment guarantees lifetime and function. Regular maintenance improves these valuable equipment and helps to lower the expensive building project downtime.

Regularity of inspection hydraulic hammer for a skid steer loader If they last, attachments have to be routinely reviewed. Before use, operators should aesthetically check the hammer and its components for wear and tear. Tool bit chipping or broken hammer houses call for quick treatment. Ignoring such problems will cause further harm and expensive fixes. Research reveals that “a proactive approach to inspections helps catch problems early, ensuring that equipment operates at peak performance.”

Apart from looking at the hammer, hydraulic hoses and connections also have to be inspected for damage or leaks. Little hydraulic line leaks might lead to significant fluid loss, therefore restricting attachment power and efficiency. Look for fluid gathering or wet areas near hose connections. Right away also corrected are kinking and fraying of the hose. Constant maintenance of these parts improves worker safety and hydraulic hammer performance.

The functionality of the attachment depends considerably on its position and alignment. Misalignment might lead to uneven hammer wear and vibration, therefore jeopardizing the operator and machine. Following product instructions during installation helps operators position and connect the hammer. This behavior improves output and reduces mechanical component wear, therefore preserving the equipment condition.

Regular inspections will help to significantly reduce predicted repair costs and downtime. Regular operations inspections allow building site managers to educate staff members on maintenance awareness. It is stated that consistency in inspections results in better decision-making regarding repairs and replacement parts, so saving time and money.

Techniques for Lubricating

Skid steer loader hydraulic hammer attachments keep their intended operation and lifetime with regular maintenance. Lubricating moving components increases performance, lowers friction and wear. Consistent lubrication helps to prevent expensive downtime and repairs. Little preventative maintenance goes a long way, said 15-year heavy machinery expert Joe Anderson. Components may overheat or shatter without enough lubrication, therefore limiting their performance and maybe resulting in work site risks.

Among hydraulic system-specific lubricants operators should choose premium hydraulic oil and grease resistant to high pressure and temperature variations. One can guarantee consistent distribution of grease fittings using a grease cannon. Pollution is another problem brought about by over lubrication.

For equipment running in demanding conditions, including construction sites with too much dust or moisture, lubrication should be done every few hours. A weekly schedule might be sufficient for equipment in less demanding situations. Maintaining a maintenance diary will enable operators to monitor and guarantee correct filling of lubricant intervals.

Manual of Maintenance: Reference Order of Order organizing

Usually neglected in maintenance, longevity and maximum performance of the Skid Steer Loader hydraulic Hammer Attachment depend on regular cleaning after every usage. Starting with attentive examination, the procedure gets rid of any garbage or dirt that could have collected while running. Blast dirt and dust with a high-pressure washer guarantees that every component is free of contaminants.

Eliminating rubbish will help to prevent corrosion; consequently hydraulic hammer performance can change. Moisture found in dirt and grime would lead to hammer and mounting point corrosion. Regular cleaning lowers certain dangers and helps employees maintain the condition of their tools.

For big equipment especially, operators should use non-corrosive tools and cleansers. Professional degreasers may aid with harder stains; for normal cleaning, mild detergues and water work best. On fragile surfaces, towels or soft-bristle brushes assist to avoid scratches.

Hydraulic hammer for a skid steer loader Attachment lifespan may be much enhanced by operators that follow good cleaning, suitable solutions, and regular component inspection. Giving these ideas primary priority will help to increase operational efficiency and provide safer working conditions on construction sites.

System Maintenance for Systems Based on Hydroulics

Regular hydraulic system maintenance determines the performance of a skid steer loader. To be sure hydraulic fluid levels fall within manufacturer recommended range, operators should check them. Low fluid levels might provide inadequate lubrication, therefore reducing performance and accelerating component wear.

As suggested by manufacturer or every 1,000 hours of operation, changing hydraulic filters helps operators assure maximum hydraulic performance and prevent expensive problems.

First looking at hydraulic fluid levels, filter condition, hose and connection leaks, operators should next look for unusual movement, weird noises, or lack of running power. Should issues still develop, a qualified technician might be called upon.

Successful Operations Strategies

Operating the Skid Steer Loader hydraulic Hammer Attachment under constant and controlled pressure will help to maximize performance and minimize damage. Early hammer and component wear might result from too aggressive application.

Another very essential component maintaining the hydraulic hammer in function is running in line with requirements. Every file contains plenty of guidelines on operating pressures and advised techniques for various uses. For exceptionally hard surfaces, several manufacturers warn against using the hammer without pre-drilling as this may strain the connection.

Regular training sessions may teach operators best methods using the Skid Steer Loader hydraulic Hammer Attachment. Encouragement of situational awareness and offering useful job-related examples helps to increase performance and safety.

Correct running techniques, manufacturer instructions, and operator training define the lifetime and effectiveness of a Skid Steer Loader hydraulic Hammer Attachment. These laws ensure that construction projects are safe for everyone and help to safeguard the equipment.

Dealing with Typical Issues

Although regular maintenance considerably lowers the possibility of skid steer loader hammer issues, operators should constantly be on watch for indications of failure or decreased performance. Usually pointing to a developing problem are strange noises, low impact force, or evident oil leaks around hydraulic connections; prompt treatment may help forestall more significant damage and costly repairs.

First operators should look for wear and corrosion on the hammer and related components; second, they should inspect the hydraulic system by looking at fluid levels and hoses for leaks. Should the hammer fall short in delivering the required impact force, hydraulic pressure might be the root of issues. Using a pressure gauge, operators can make sure the system is working as makers intended.

Novices should not try to solve difficult issues such internal cylinder failures or severe hydraulic malfunction. See a licenced technician to guarantee exact and safe repairs. Should a component display obvious wear or damage, replacement might be required to prevent further harm.

Apart from minimizing downtime, frequent inspections and timely resolution of issues help to improve project site efficiency and skid steer loader reliability.

Notes Regarding Seasonal Fix-through

Operators and maintenance managers have to change with the seasons to guarantee perfect Skid Steer Loader hydraulic Hammer Attachment performance. Low winter temperatures, for instance, might thicken hydraulic fluid, therefore lowering performance.

Getting ready for harsh weather calls both attachment. Look check the seals and hoses on the hammer for leaks before big rain or snowfall. Water ingress could harm and corrode components. Furthermore lessening corrosion on exposed metal components is achieved by applying a protective coating.

Cleaning off-seasons for the Skid Steer Loader hydraulic Hammer Attachment helps to collect rubbish and debris that may otherwise cause uncontrollably fast corrosion. Storing the attachment in a climate-controlled location will help to guard it against moisture and excessive temperature swings if at all feasible.

In the maintenance of heavy equipment, seasonal maintenance problems take center stage. Operators may maintain their Skid Steer Loader hydraulic Hammer Attachments in perfect form year-round by changing maintenance schedules to meet seasonal circumstances, being ready for inclement weather, and using appropriate storage techniques.

Expert Repairs and Maintenance

Unusual vibrations or sounds experienced during operation, for example, might point to internal damage or wear calling for professional inspection.

Professional operators on balancing their degree of understanding in relation to the seriousness of the issue. Small problems including lubricating components or seal replacement might be handled by a competent operator. One should contact a qualified specialist for noteworthy hydraulic leaks or performance decreases.

To remain current on the newest technologies and repair techniques, operators should hunt personnel accredited by reputable manufacturers or firms. Online reviews and testimonies might also provide particular information about reliability and work quality of a service provider.

Although skilled operators may handle basic maintenance, skid steer loader hammers will last longer and perform better if one understands when to consult experts and assures access to qualified labor. Giving professional maintenance first attention helps to eventually reduce downtime and increase production on construction sites.

Take Advantage of this Outstanding Lifelong Guidance

Regular wear and tear inspections, meticulous lubrication, and complete cleaning after every usage characterize proper maintenance of a skid steer loader hydraulic hammer attachment. Maintaining an eye on the hydraulic system and adhering to best operating practices also helps to prevent expensive repairs and downtime.

First priority should be given to these maintenance approaches by construction equipment operators and technicians thus enhancing the performance of the project and skid steer loader hydraulic hammer attachment. Regular maintenance charges will pay off handsomely in reliability and performance, therefore guaranteeing that the equipment stays a valuable asset in every construction project.