Seasonal Maintenance Tips for Skid Steer Loaders

Whether your skid steer is used for construction, landscaping, agriculture, or snow removal, the decision to buy one is still a major one. They don’t make these machines small and weak, but to keep the same level of power all through the year, proper seasonal skid steer maintenance is a must.

Every season has its own in feeds and difficulties which can bring a halt to the normal work of the machine if not taken care of (e.g. frozen hydraulic lines in winter, clogged radiators in summer). Moreover, such situations will shorten the life expectancy of the equipment. Contractors that year-round skid steer maintenance tips are more than just proper care of their machines sometimes they are a key to uptime that contributes to safety and equipment life-extension.

The idea is to walk through carrying out the maintenance on the different seasons to ensure the survival of the skid steer in any weather condition while practicing the new methods of the experts.

Seasonal Maintenance Tips for Skid Steer Loaders

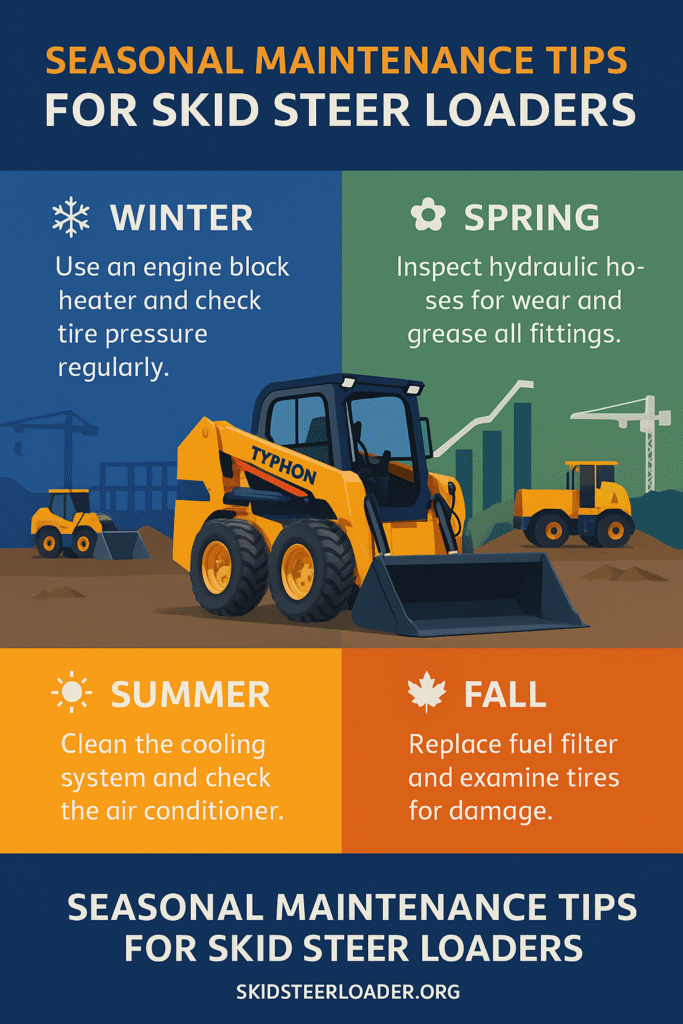

Spring Skid Steer Maintenance

Quite often, the winter off period is the time when the transition to the new season takes place and in such cases, the transition season is spring, pretty much for the operations as well as for the equipment itself (skid steer loader in this case). Inspection of damages, cleaning the machine that is still part of the work and heavy loading preparation should be the main works at this time.

Some of the main spring works will be:

- Thorough Cleaning and Inspection: Get rid of any salt, mud, and other solids which have built up on your machine during winter to avoid corrosion. Any areas that are underneath the vehicle, the hydraulic hoses, and the couplers might be suffering from small leaks or cracks as a result of the cold – ensure that you have these checked.

- Fluids Replacement: Besides replacing engine oil, hydraulic fluid, and coolant, you can easily top off the fluids that are still good. Spring is the perfect time to change fluids that have become old and thick and move to the ones that are recommended for warmer conditions.

- Filter Maintenance: To make sure that no winter dust or debris is inside the system, all filters — engine air, oil, hydraulic, and cabin — must be changed. At the time when filters are dirty, airflow and engine power can be limited during heavier workloads.

Just by doing a thorough spring clean and system flush, you can really prepare for a high construction season. Don’t forget that a lack of care for the spring skid steer is mostly the cause of the sudden failures that occur right in the middle of the project.

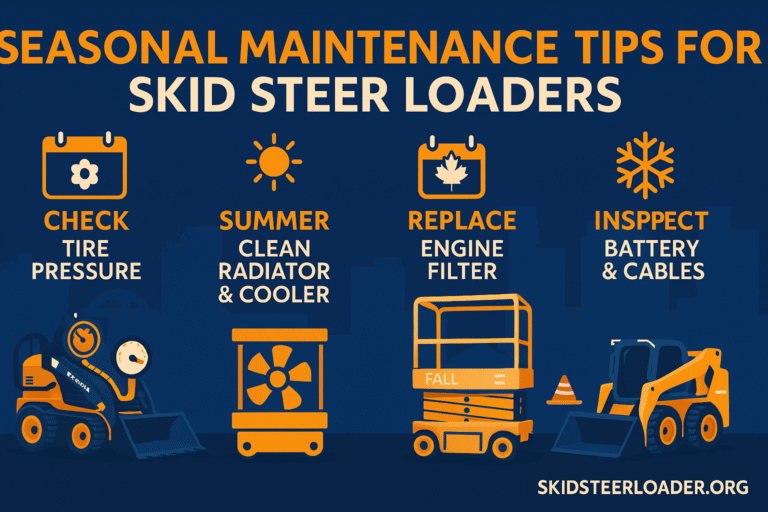

Summer Skid Steer Maintenance

Summer implies endless hard work for skid steers mainly in agriculture, landscaping, and material handling. The large amount of heat that exists during summer can make cooling, lubrication, and the comfort of the operator a real nightmare, and this is why they become the focus of this season.

- Cooling System Check: Do a weekly inspection of radiators and coolers. Include not only people but also machines in your clean-up operation. Remove the small cutting, or dust particles that are often found in an airflow path. Overheating is a very common summer problem in disguise.

- Tire and Track Care: The heat of the day can make a very good friend of a tire turn into a dangerous foe. What happens is the air inside the tire expands and the tire pressure increases. Follow the manufacturer’s instructions on what the ideal tire pressure should be. Don’t limit the safety measure to just one, if you have a tracked skid steer, check its tension to avoid that tracks wear out too fast.

- Cab Comfort and Safety: Since the operators are to be found inside the cabin for such a long time, that is why they have to be comfortable, because the cabin is under the scorching heat all the time. So make sure that the maintenance of the cabin air conditioning, fans, and seat ergonomic is just what they need. Hence the conclusion: Comfort for the operator is no less important than the machine health because an operator tired of summer heat could easily make a mistake.

One of the most important things during a hot season is regular grease lubrication. This is necessary in order to fight against the excessive dust and the exposure to the sun. You should always check grease fittings every day because they are more prone to drying out due to the heat. This season demands very strict preventative maintenance in order to avoid the breakdowns that occur in the middle of the day.

Fall Skid Steer Maintenance

Generally, fall is the time of the year when the changes are made and the skid steers get ready for the winter period with all the difficulties that come with heavy snow and icy terrain. Preventive maintenance reduces the risk of failure and ensures safety during the coldest months.

- Hydraulic System Readiness: Feel the hydraulic fluid lines for any leaks, cuts, or softness. The wires that are weak can be broken by the cold so that fall is the best time to replace them.

- Lighting System Inspection: During fall the days become shorter. By replacing or upgrading the skid steer lights like LED work lights, cab lights, and hazard markers you can give your machine the proper illumination that will ensure safer operation during long fall evenings.

- Attachment Inspection: Consequently, if you are going to change from warm-weather attachments such as buckets or pallet forks to snow blowers and snow pushers, you can quickly and easily service the quick release, lubricate the pivot points with grease, and check the lock systems for wear.

The autumn season maintenance is about getting your skid steer loader ready for winter. The well-prepped machine makes sure that the transition into heavy winter work is done without any problems and the high seasonal downtime that happens during the winter is avoided.

Winter Skid Steer Maintenance

Winter is the most unpleasant season for skid steers. The temperatures below zero, the frozen hydraulic fluids, and the snow that is packed on the jobsites test to the utmost every part of the machine. Winter proofing is the only way to guarantee that your loader will not only start reliably but also operate efficiently in freezing temperatures.

- Cold-Weather Fluids: Opt for winter-grade engine oil and hydraulic fluids that have low-viscosity nature. The thinner fluids make it possible to achieve faster flow rates even in very cold temperatures.

- Battery Health: The cold weather is a great enemy of the battery as it drains the battery power very quickly. So make sure to test the battery voltage, carry out a visual inspection of the terminals, and always keep a backup jump starter at your disposal.

- Pre-Heating Solutions: The use of engine block heaters and hydraulic line warmers is one of the causes of a headless start condition in the car, which is softened and this is because of the less stress on the components. This, at the same time, very much reduces the wear that is being caused and gives the air that is working the rest of the way until the startup is accomplished.

Operators can also contribute to winter safety and comfort by applying the below steps. Periodic snow removal from the equipment under the snow is one way of leading to maximum productivity in winter. Moreover, keeping the cab heated is beneficial not only for cab comfort but also for maintaining the windshield free from fog or mist.

Winter is hard on the equipment but if the skid steer winter maintenance is diligently done your machine can make a downfall in the difficult situation.

Year-Round Preventive Maintenance Checklist

Certain maintenance duties are essential and must always be a part of a well-prepared year-round plan that takes into account the seasonal variation of conditions in order to prolong the service life of your skid steer loader.

- Daily Inspection: Perform daily visual checking for fluid levels, the wear of tires and tracks, hoses, and attachments.

- Daily Maintenance: Routines such as cleaning, lubricating, and retightening the machinery if necessary should be a part of daily schedules.

- Periodic Services: Follow manufacturer-recommended intervals of service for oil and filter changes, hydraulic fluid, transmission fluid, and coolant changes.

- Tire/Track Care: Maintain proper air pressure in tires, regularly inspect for cuts, punctures, and abnormal wear, rotate if needed, and replace when worn beyond minimum tread depths. For tracks, keep the right tension, check for damage, clean the undercarriage, and replace when worn

- Servicing Scheduled: Service the machine as per manufacturers guidelines for oil changes, filter changes, lubrication, and adjustments.

- Training of the Operator: The operator who had been given a proper training to operate the machine is the one that is going to be able to spot the first signs of machine’s failure. The continuous operator awareness is a very important factor for the long-term performance of skid steer.

Sample Table of Preventive Maintenance Schedule:

| Maintenance Task | Daily | Weekly | Monthly | Seasonal |

|---|---|---|---|---|

| Walk-around inspection | ✔ | |||

| Grease all fittings | ✔ | |||

| Check hydraulic fluid levels | ✔ | |||

| Radiator cleaning | ✔ | ✔ | ||

| Oil & filter replacement | ✔ | |||

| Tire/track inspection | ✔ | Season | ||

| Cab filter change | Season | |||

| Lighting & battery check | ✔ | Season |

This is only a rough maintenance schedule which can be changed to fit your working conditions and specific machine model.

Skid Steer Maintenance: Common Mistakes

Unintentional owners of skid steer loader often make a huge mistake in that they overlook a very important thing the maintenance of the machine, and this is what shortens the lifecycle of the machine. If you want to keep your machine in good condition, then you should refrain from these mistakes:

Not Following the Manufacturer’s Recommendations: Always follow the guidelines in the operator’s manual, including the types of fluids, filters, and service intervals.

Working Operating Without Inspection: A few small problems, like a tiny leak or a hose that has come off a bit, can turn into a big breakdown if they are not found.

Improper Storage: Parking skid steers outside without covering them with a protective skid exposes them i.e rust, fluid thickening, and electrical failures. The avoidance of such errors will ensure the continued reliability of your skid steer throughout seasonal changes.

Benefits of Seasonal Maintenance

Why would one go the extra mile to carry out the seasonal maintenance? In a nutshell, the main reason is that preventive care leads to savings and efficiency gains.

Reduced Downtime: Small problems, if caught early, can lead to a chain reaction that will end in slow or even no breakdowns and project delays.

Improved Operator Safety: Along with well-maintained controls, hydraulics, and lighting, a well-lit environment can improve job site safety.

Extended Machine Life: Regular fluid checks, filter changes, and part replacements keep your skid steer doing its job efficiently for a long time.

Good maintenance confirms the general profitability of the business, especially for those dependent on the uptime of the equipment like contractors, farmers, and landscapers.

FAQs on Skid Steer Loader Maintenance:

How often should I grease my skid steer loader?

Greasing should be done daily if the equipment is used heavily, or at least every 8 hours of operation to keep joints and moving parts lubricated.

What fluids are recommended for the winter use of a skid steer?

Low-viscosity engine oils and winter-grade hydraulic fluids are the essentials for a smooth operation in very cold temperatures. Always adhere to your manufacturer’s advice.

Is it possible to operate a skid steer without changing filters every season?

Though it may not be necessary every time, changing filters at least once a season can enhance fuel efficiency, airflow, and also keep the system clean from contaminants.

What is the reason for the overheating of my skid steer during summer?

The most common reasons for this are blocked radiators, low coolant, or poor airflow. Regular cleaning and coolant level checks are a must during hot weather.

What are primary symptoms of hydraulic failure in skid steers?

Hydraulic issues may cause noisy pumps, slower function response, visible leaks, and heating of the hoses. These signs require instant intervention.

Is it obligatory for skid steer vehicles to be stored in a garage during the winter season?

It is deeply advised indoor storage so as not to face freezing of the fluids, battery discharge, and rust damage. In the case of a non-availability of indoor storage, use covers and block heaters.

In what way can maintenance activities help improve the resale value of the skid steer?

Not only first but also last maintenance records, including seasonal service checks, have a big impact on resale prices, as buyers get confidence in the machine’s condition.