Reveal Precision: How the High-Torque Augers Take Over Fencing and Tree Planting

If you are a landscaping professional, an agricultural expert, or a fencing contractor, you know how essential good equipment is. Doing the drilling work with a regular attachment when the ground is hard could mean the bolts on the equipment will break, the hydraulics will get overheated, and the manpower wasted. The High-Torque Skid Steer Auger from skidsteerloader.org is there for you in such situations.

- With a design for tremendous power and vertical accuracy, these attachments are not only tools but the perfect partners for efficient fencing and planting trees on a large scale.

- We at skidsteerloader.org know that just “good enough” won’t get you through 500 fence posts before the raining or rootball saplings shipment that needs the ground straight away.

- Our top range High-Torque Skid Steer Auger uses advanced planetary drive technology to give a steady drilling force resulting in the perfect depth and diameter for each hole.

The burden is no more on manual labor; instead, it is hydraulic precision that operators utilize to get cleaner holes with such vertical integrity that manual digging cannot do. It doesn’t matter if you are a veteran contractor or a landowner with a large property; an upgrade to a high-performance auger will be the most productive decision you will ever make.

Features of High-Torque Skid Steer Auger

Planetary Drive Technology Power

The amazing secret of a High-Torque Skid Steer Auger is the internal planetary gear reduction that engineers have used instead of the external chain drive motor that is cheaper but produces a loose pressing and a mechanical failure.

Planetary drives are gears that are protected by a case and multiply the torque of the motor of your machine’s hydraulic. That big force is what makes it possible for an auger to deeply dig into tightly packed dirt, shale, and even concrete without slowing down the host machine. By buying a product from skidsteerloader.org, you will get a hydraulic unit that is capable of turning water flow into a powerful and dazzling force.

The motor torque keeps the same level even if the soil resistance suddenly changes. A basic direct-drive auger may be able to run quickly in loose sand, but it will refuse to work once it meets a tree root or a clay pocket. Our units maintain their shaft speed even when overloaded and therefore allow a faster work process.

Time saved in a single hole adding up to a few hours in the whole day. Also, the sealed gearbox makes it possible for the parts to last longer because they are always lubricated with oil and protected from dust and dirt.

- Uniform Torque Output: The gears in the planetary system keep the torque delivery even and thus prevent the stalling effect experienced in direct-drive systems when there is a hard impact.

- Low Maintenance Costs: By enclosing the gears in a sealed housing, the frequent chain retightening or greasing of the exposed parts will not be necessary, which means more working time and less maintenance time for you.

Super Precision Vertical Digging for Fencing

Fencing is a very artistic job, but mathematical exactness is what determines whether it will be considered successful or not. For instance, a fence post that is only off by a few degrees can result in the weakening and deformation of the fence line.

By utilizing a High-Torque Skid Steer Auger from skidsteerloader.org, a very high degree of vertical accuracy can be obtained and this is almost impossible to achieve with a handheld gas auger or a tractor PTO unit.

- The articulating arms of a skid steer allow an operator to precisely and effortlessly position an auger bit perpendicular to the ground. This is essential for professional fencing projects where clients ask for perfectly straight lines and equally spaced intervals.

- On top of that, the “plumb- line” skill that comes with random skid steer well is made possible mainly by the rugged construction of our auger mounting. The double-knuckle joint permits the auger drive to remain completely vertical irrespective of the loader’s terrain.

- If your machine is on a slope, your bit again will tend to be straight because of gravity, and that is one of the many reasons why the high torque is able to carry on with the bit’s path as it digs.

This automatic centering greatly reduces the digging work that involves manual hole correction and filling with a spade. When you put a post in the hole, it will stand upright all the same. In high-tensile wire or privacy fences where the wire tension is the prime factor, this vertical precision coming from the inside proper alignment will be crucial to the efficacy of the fencing.

- Self-Centering Feature: The auger is held perfectly plumb irrespective of how uneven the ground may be by the universal joint linkage, thus vertical post installation is guaranteed on every occasion.

- Bit Walking Extinction: The Pilot bit is pressed into the ground immediately, so there is no run for the auger though the grass, the high torque and the weight of the drive unit combination, respectively, being the reason for this.

- Regular Hole Size: The rotation of the bits at a constant speed will make regular, round holes and by that, each post will need less concrete, the cost of the materials for each post being saved.

Focus Tree Planting Operations

Tree planting is something that requires a different kind of approach from fencing; essentially, it is not just opening up a hole but creating a root-friendly environment that is the goal and A High-Torque Skid Steer Auger equipped with a tree planting bit is one of the best tools for this purpose.

The bits could be tapered or of a larger diameter for the accommodating of root balls, and simultaneously, high torque facilitates the powdering of the soil during soil extraction. The fluffed soil at the bottom and the sides of the hole is vital in preventing the flower pot effect where water gets trapped in smooth, compacted walls without getting absorbed by the roots resulting in the death of the tree.

Furthermore, the rapid planting of trees is very essential in orchards, nurseries, or reforestation projects. Hundreds of saplings going out of the ground at the same time means that the exposure of little roots to the air has to be minimized.

Therefore, a single operator can efficiently keep ahead of the rest of the planting crew with a High-Torque Skid Steer Auger forestry unit. A reversal function of the auger doesn’t only give an operator the option to get back soil into a hole but also to make the bed more accommodating for a new tree.

Soil Adaptability: Rock, Clay, and Frost

Everybody know how frustrating it is when an operator faces a soil type that his/her equipment cannot handle. For instance, a normal auger that is fine with a loam might run helplessly against caliche, shale, or frozen ground. The High-Torque Skid Steer Auger products made by skidsteerloader.org are very specifically designed to tackle these/substrates.

If you have the right “rock bit” or Different soil types need different bits. Changing the bits depending on the type of soil is the right thing to do. However, in heavy clay, thanks to the high-torque motor, the sticky soil won’t stall the flighting and, in rock, the motor will provide the low-speed, high-force grinding action needed to chip away at the stone.

This means that with a properly cared-for drive unit, you will have an investment that will do your year-round job: drilling fence posts on rocky summer soil and planting winter-hardy trees on frozen ground. In addition to that, it prevents your having to rent a special drilling rig for each tough job, hence more profit stays in your pocket.

- Change Bits: Instantly switch between regular earth bits, heavy-duty clay bits, and carbide-tipped rock bits to meet the demands of a job site.

- Cracking Force: With low-speed, the huge torque effectively breaks off rock and shale whereas the high-speed ones just glaze the surface.

- Winter Ready: Capable of drilling down past the frost line, thus allowing fencing and construction projects to continue even during the winter months.

Technical Specifications and Compatibility

skidsteerloader.org places a lot of emphasis on compatibility and user-friendliness. Our High-Torque Skid Steer Auger is designed with a Universal Quick Attach plate of industry standard, making it compatible with almost all skid steers, track loaders, and compact utility loaders.

Besides mounting, hydraulic compatibility is the key as we offer drive units for different hydraulic flow rates appeared, from standard flow (10-20 GPM) up to high flow (25-40 +GPM) machines. Max torque delivery and motor seal damage prevention can be achieved only by matching the auger drive to the hydraulic output of your machine.

Also, the output shaft is one of the most important parts where high strength is needed. A large two-inch hex output shaft is equipped on most of our high-torque units. When exposed on all four sides and corners, the hexagonal form offers a much better grip than a round shaft.

This means that even under the highest solid load, the risk of the bit’s stripping on the shaft is virtually zero. With this rock-solid connection, 100% of the hydraulic power goes directly to the digging teeth. Heavy-duty drill pipe extensions are available under our augers if you are looking for deep excavation. So, you can dig beyond the typical 4-foot depth, which is great for pole barns or utility poles.

- Universal Quick Attach: Compatible with all major skid steer brands (Bobcat, Caterpillar, Kubota, etc.) without the need for costly adapters or aftermarket modification.

- 2-Inch Hex Output: The industry-standard heavy-duty shaft prevents slippage and wear, ensuring maximum power transfer to the auger bit.

- Flow-Matched Motors: Different models are available, each one optimized to the specific gallons per minute (GPM) rating of a customer’s machine to ensure maximum efficiency and safety.

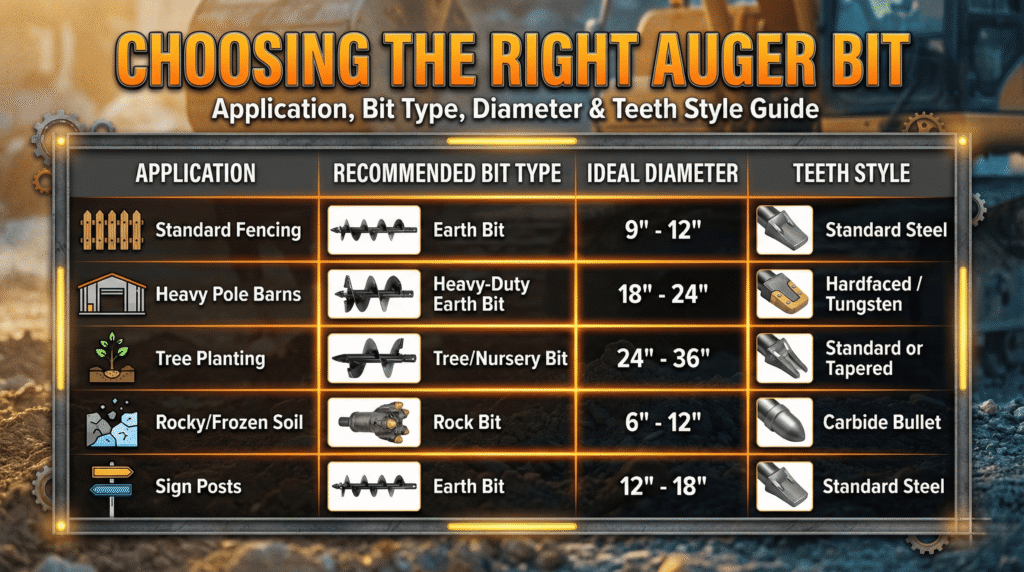

Table: High-Torque Skid Steer Auger

| Application | Recommended Bit Type | Ideal Diameter | Teeth Style |

| Standard Fencing | Earth Bit | 9″ – 12″ | Standard Steel |

| Heavy Pole Barns | Heavy-Duty Earth Bit | 18″ – 24″ | Hardfaced / Tungsten |

| Tree Planting | Tree/Nursery Bit | 24″ – 36″ | Standard or Tapered |

| Rocky/Frozen Soil | Rock Bit | 6″ – 12″ | Carbide Bullet |

| Sign Posts | Earth Bit | 12″ – 18″ | Standard Steel |

Safety and Maintenance for Longevity

Any investment is best preserved when properly maintained, and a High-Torque Skid Steer Auger is no exception. Luckily, at the level of maintenance, planetary drive design is very simple, but even so, a few routine checks are a must.

Check hose condition regularly and look out for wear and abrasion. A blown hose under pressure is very dangerous and it can make a mess. In the same way, an annual or 500-hour change of planetary gear oil is necessary so that the gears remain cool and lubricated from the inside.

It is extremely important to have safety considerations in mind when using high-torque powered machines. Because of the very high torque, it is necessary that any person who is not involved in the work should keep away from the drilling site.

With a skid steer, the “kickback” is hardly any compared to a handheld unit, but because of the machine’s weight, it can still be knocked out of position if the auger suddenly catches a solid immovable object.

If the machine has stabilizer steps, the operator should always use them and never use one’s hands or a shovel to get rid of soil from a rotating auger. skidsteerloader.org offers safety manuals and guides for every piece of equipment that they sell. These printing materials will help you understand some safety tips and tools to make crew work safe and efficient.

Check the condition of the hose on a daily basis: specific checks for leaks or abrasions should be carried out in order to avoid downtime and contamination of the fluid.

- Gear oil: The simple annual fluid change for the planetary drive will allow the gears and support surfaces to run smooth and cool for decades.

- Safe working area: One can prevent accidents and assure the safety of the working crew by marking out a clear “danger zone” radius around the working auger.

FAQs for High-Torque Skid Steer Auger

How big auger bit shall I use for 4×4 fence post?

The top search results state that for a 4×4 wooden post of standard size, it is recommended to use an auger bit that has a diameter of at least 8 to 10 inches. Technically, a 6-inch hole would be sufficient for the post but that leaves just about zero space for backfilling the concrete or tamping the soil with which to secure the post. An 8 or 10-inch hole is enough to provide the necessary adjustment space and will also ensure the post is well set in concrete.

How deep can I dig using a skid steer auger?

A typical High-Torque Skid Steer Auger bit has a length of 4 feet (48 inches). On the other hand, significantly greater digging depths can be obtained by using extensions. Common extensions vary in length from 12 inches to 72 inches. Equipped with the right extension and a high-torque drive unit, you will be able to dig as far as 6 feet or even deeper, a depth that is generally required when working on pole barns or utility poles. Usually, the limiting factor is the machine’s lifting height and hydraulic capacity.

Does a skid steer need to be high-flow for an auger attachment?

A no is an answer to that question because a High-Torque Skid Steer Auger attachment is made for both standard-flow (10-20 GPM) and high-flow (25+ GPM) skid steer machines. The important part here is that the hydraulic auger motor should be compatible with the flow rate of the machine. A standard-flow machine used with a high-flow auger will perform at very slow speed and produce very low torque while a high-flow machine running a standard-flow auger can potentially experience motor seal damage due to the excessive pressure.

Would a skid steer auger be able to bore through a solid rock?

Answer to this is, yes, but only if the right tools are available and used appropriately. A regular earth bit would simply not make it through a solid rock. You have to first, go for a Rock Auger Bit that has carbide “bullet” shaped teeth and a stubborn boring head. On the other hand, a high-torque planetary drive is a must for rock drilling since it gives the slow, grinding force required to crack the stone. A particular rock setup is necessary if you normally have to work on rocky soil.

What do I do when my skid steer auger is running but no soil is coming out?

The most typical reason behind such a situation is teeth that are worn out or a pilot bit that is no longer sharp. The pilot bit’s job is to drag the auger down into the soil. If it is round, the auger will be spinning on the surface only. Other reasons may be the fact that you have come up against a rock that cannot be penetrated, the loader arms are not exerting enough downforce, or the bit size is too big for available machine torque.

Is it possible to use a skid steer auger for tree planting?

Yes. For setting trees, the High-Torque Skid Steer Auger is among the best tools to be used. For even better results, it is recommended to use an auger bit that is specifically designed for tree planting. Typically, such bits are tapered (narrows down at the bottom, and widens at the top).

Or they can be simply large diameter (24-36 inches). Their main function is to fluff up the soil instead of compressing the sides, which enables the newly planted trees roots to easily penetrate the surrounding earth. Not only is this way a much quicker process but also the tree becomes healthier compared to the digging with a backhoe bucket.