Skid Steer Loader Controls Explained: Master Your Machine in Days

The quickest way to access the full range of productivity, skid steer loader controls mastery is one of the best tricks you can use though with no prior knowledge. This comprehensive guide for skidsteerloader.net embarks on the mastery journey with main control patterns, hand and foot coordination, safety best practices, attachment handling, and pro-level tips that are sure to bring any operator on his/her machine through days.

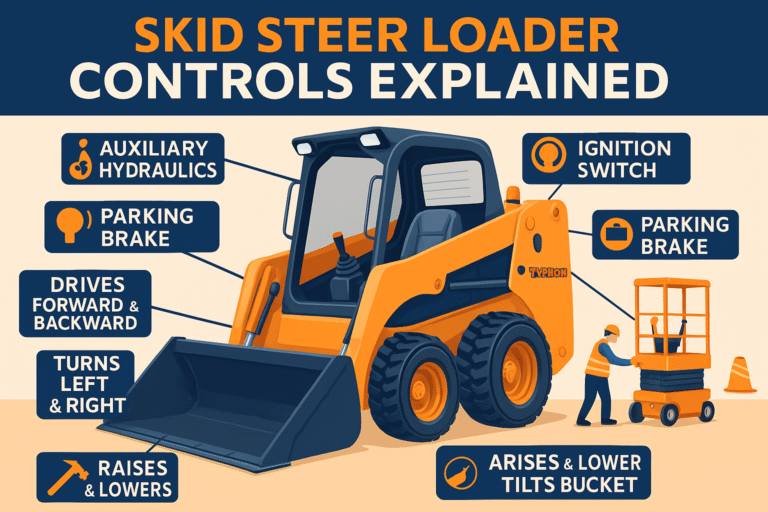

Understanding Skid Steer Loader Controls: The Basics

The latest skid steer loader is a handy little thing that can pretty much do anything you ask such as digging, grading, trenching, snow removal, material transport, and a variety of specialized tasks. The secret of these machines is the understanding of their astonishing instrumentalities and a perceptive handling. Control installations are generally either dual joysticks (or foot pedals), or a combination of both, depending on the manufacturer and the generation of the machine, but the basics are the same throughout the industry.

Skid steer movement or “skidding” is a way whereby you turn the loader by one side rap idly spinning one set of wheels. Thus the zero radius turn is allowed, with the loader able to move fast and tightly even in the limited spaces of a jobsite.

Operator cabins contain either open or enclosed cabs, which have ergonomic controls, adjustable seats, and instrument panels designed for the maximum operator’s comfort and safety during long shifts.

Safety features—such as lap bars, seat belt indicators, and interlock systems—are always there to protect the operator no matter if the loader is running or not. The right mastery of these basics not only decreases the learning curve but also lowers the risk and increases the productivity from the first day.

Control Patterns: ISO, H-Pattern, and Standard Controls

One of the main things to consider while learning the operation of skid steer loaders is the understanding of various control patterns, namely, ISO (International Standards Organization), H-Pattern, and Standard (foot and lever) controls.

The majority of contemporary machines provide selectable control patterns as a feature, so that the operators can pick according to their comfort. Before starting to work, it is a must to find out what pattern the machine uses.

- ISO Controls: In the ISO layout, the left joystick manages travel (forward, backward, left, right), while the right joystick takes care of the lift arms and attachment tilt. This pattern is preferred for the simplicity of learning and the lowering of the operator’s fatigue.

- H-Pattern Controls: H-pattern is a method whereby two joysticks are used to control left and right drives (mobility) separately. Additionally, the left joystick is responsible for the raising/lowering of the boom whereas the right is for the bucket tilt, which is very similar to the older lever-based designs.

- Standard Pattern (Levers and Foot Pedals): Some older or cheap machines may be equipped with hand levers for movement and foot pedals for lifting/lowering the boom or tilting the bucket. These types of machines need more physical effort to operate and also more experience in handling.

Skid Steer Loader Controls Patterns Comparison

| Pattern | Travel Control | Lift Control | Tilt Control | Ease of Use |

|---|---|---|---|---|

| ISO | Left joystick | Right joystick | Right joystick | High |

| H-Pattern | One joystick per side | Left joystick | Right joystick | Moderate |

| Standard | Hand levers | Foot pedals | Foot pedals | Lower |

- Controllable Joystick (SJC) a new technology featured in many machines lets the on-board operator switch the control from one ISO to a different H-Pattern directly in the cab.

- To make sure no mistakes occur, as well as no confusion to arise, always use a machine manual or control schematic to guide you in operating a new loader model.

- Knowledge of several patterns strengthens the user’s ability to handle rental equipment and work efficiently on various jobsites.

Hand and Foot Coordination: Joysticks, Levers, and Pedals

It is of utmost importance to hand and foot coordination which will allow the user not only to bass the safety principle but also to work in rapid manner. Nowadays, several joystick type steering are usually mounted on the hand units of modern skid steers which relieve the operator of the necessity of using the foot, but there are still some configurations in which levers and pedals are used.

Regarding the most common joystick setup:

- The left hand (ISO) moves the loader in the directions up, down, left, and right.

- The right hand (ISO) controls the lift arms, that is, the user can raise, lower, and untwist the arms.

On older lever-and-pedal machines:

- Hand levers change the direction of the loader (left wheels/right wheels).

- Foot pedals or heel-toe operations manage the boom lift and bucket tilt.

Operators can improve their coordination significantly through practice, but they should always:

- While doing so, they should maintain a good posture and both feet should be flat on the floor, hands should be lightly gripping the controls.

- Not make sudden or fast movements. Controlled and deliberate inputs will result in a safer and more professional operation.

First of all, one should know the control layout by heart before starting the machine—practice the smooth hand movements for the complex maneuvers and multifunction usage.

Advanced maneuvers: Turning, Skidding, and Positioning

Actually, the reason of coining the term “skidding” for the turning method is the way a skid steer loader makes its turns. The loader does not turn by wheel angling but it turns by the one side speed being lower than the other, thus zero-radius turns are possible even in tight spaces. The full capacity way of performing with the machine is the real power of the loader revealed.

- Skids can be executed by moving one joystick full forward and pulling the other one back full (in H-pattern). The second way is by using the left joystick in ISO to slowly transition from forward motion into a pivot.

- If the tracks or wheels on the two sides of a differential steering vehicle are reversed, it means that the vehicle can make tight, efficient turns with little or no damage to the surface, provided that the turn is properly controlled.

- Expert operators often practice “feathering” their turns—that is they slow down before a sharp pivot so that they can avoid jerking, minimize the damage to the turf, and at the same time keep the machine balanced.

- In all cases, you should position yourself where you want to move, use the mirrors or the camera system (if available), and most importantly do not stop, turn suddenly or do it on a slope which is not flat, a weak surface or soft ground.

- Tracks off machines are less likely to be damaged if the driver takes the loaded vehicle down the road slowly turning in a looks like a small curve at the end of the road and so on gently-made turns on the road surface would not cause the scarring of the road surface which would, in turn, extend the life of the undercarriage of the vehicle.

- Avoid using the landmarks and minor inputs for overcorrecting, rather just use them to line up the loader for your long straight path.

- Regularly drill three-point turns, parallel parking to a trench as well as exact alignment with attachments or dump trucks for loading/unloading—these skills make efficient work exponentially.

Multi-Function Operation: Attachments, Hydraulics, and Couplers

Skid steer loaders are well known for their versatility. The term “Mastery” is not limited to the machine alone but rather it also extends to the various appliances—buckets, forks, augers, grapples, sweepers, and so on and so forth—that come with the loader.

- One has to be very comfortable with the use of auxiliary hydraulics, couplers, and in-cab switches in order to have complete control over the attachment.

- Modern loaders typically have quick-attach couplers—manual, hydraulic, or electric—that allow for quick, safe switching between different tasks. Always, when you “shake test” the attachment being properly latched.

- Auxiliary hydraulic controls (e.g., finger switch, foot pedal, or button) that operate the specialized appliances like the grapple or the auger demand careful coordination while working.

- Recognize and respect the limits: The lift capacity of the loader and hydraulic flow rates set the stage for which attachments the machine can work with. The result of overloading the system is not only damage but also safety risks.

Before Changing the Attachments:

- Lower the lift arms, shut down the loader, and release the residual hydraulic pressure as per the manufacturer’s instructions.

- First, check the coupling for leakage or for wrestling with a well-maintained coupling avoiding the wastage of time at the most inopportune moments.

- Every hose and fitting should be tight, and you should, without fail, check if the functions of the joystick and the switch are okay for the new ones before you start them.

Safety First: Best Practices for Every Operator

There is no compromise when it comes to the safety of Operator. Skid steer loaders, though very powerful, could endanger the user if he/she acts irresponsibly. Implementing the industry-standard safety practices greatly reduces the risks and is a must for all users.

- Before the Operation: Do a 360-degree walk-around before starting. Check the tire condition, fluid levels (hydraulic, engine oil, coolant), visibility aids, and attachment security.

- Controls Test: Just after the loader is placed on a flat surface, and the parking brake engaged, verify all the movement and function of the controls. Confirm that interlock safety bars and seat belts function as expected.

Cab Etiquette:

- Don’t step in if doors or windows are open, or body parts are outside the cab.

- Before lowering the lift arms, set the parking brake.

- Only when all motion has stopped and the engine is off, leave the cab.

- Always wear the correct personal protective equipment-hard hat, safety boots, reflective vest, gloves, and eye protection.

- Watch out for people around you; use horns, backup alarms, and spotters if your view is blocked.

- Don’t ever try to ride or “surf” the loader arms.

- Get acquainted with emergency procedures like loader lowering and cab escape.

Pro Tips: Fast-Track Your Mastery in Days

If you are a novice, with the help of the right schedule, you can be becomes an efficient operator in no time. The main reason that most of the experienced professionals keep being so skillful is that they don’t stop to learn, they do the hands-on practice, and they apply these must-follow tips that one can find everywhere.

- Daily training (beginner) is best done in a practice area (open, obstacle-free) where you can do forward/reverse first, then loading, unloading, tight maneuvers, and so on at own pace.

- Video tutorials or attending directly under an expert operator can help you to grasp the technique better and get your muscle memory working.

- Master attachment handling focus: The ability to change, move, and use auxiliary hydraulics without interruption is the characteristic of a top operator.

- Every hour of operation should be logged; regular seat time is skill development that grows much faster than theory alone.

- To develop lifelong habits that benefit operators as well as employers, keep a daily checklist for machine pre-checks and cleaning.

Table: Common Loader Attachments and Skid Steer Loader Control Actions

| Attachment Type | Control Used | Typical Function | Skill Level (1-5) attachmentsking |

|---|---|---|---|

| General bucket | Joysticks/pedals | Scoop, lift, load, dump | 2 |

| Pallet forks | Joysticks | Lift, transport, stack materials | 3 |

| Auger | Joystick + hydraulic button | Bore holes, dig post footings | 4 |

| Grapple bucket | Joystick + auxiliary | Grasp logs, debris | 3 |

| Snow blower | Joystick + auxiliary | Clear snow, propel discharge | 5 |

In any case, the control mechanisms of the device may be distinct, depending on the type of attachments, so it is always advisable to examine the diagrams the manufacturers provide for each tool set.

The level of proficiency rises as the complexity of the attachments requiring hydraulics or the handling precision grows.

FAQs: Trending Topics About Skid Steer Loader Controls

What’s the difference between ISO and H-pattern controls?

ISO is a setup where the left joystick is responsible for all travel movement and the right one for lift and tilt, whereas with the H-pattern one joystick is assigned per drive side, and lift and tilt are controlled separately. Generally, ISO is considered a simpler way of learning.

Can I switch control patterns on my skid steer loader controls?

Most of the new models are equipped with a joystick control that can be selected, thus the operators are able to switch between ISO and H-pattern with a cab switch or a menu option.

Is it safe to switch attachments without turning off the loader?

No; in order to be as safe as possible, one should always park on level ground, lower the lift arms, turn off the engine, and release the hydraulic pressure before changing the attachment.

How fast can a beginner learn skid steer controls?

With proper practice and expert guidance, the majority of users can get the basic skills in a few days. Regular, safe practice is the key to the fast progress.

What PPE is required for operating a skid steer loader?

The minimum requirements are a hard hat, a high-visibility vest, safety boots, gloves, and eye protection.

How can operators minimize turf or ground damage during turns?

The operators who use gentle, arcing turns, slow down before making tight skids, and do not spin in place thus save the surfaces and the underside of the machine.

What’s the best way to practice advanced loader handling?

The best way is to select different multi-function tasks for example maneuvering while lifting or placing loads, frequently changing the attachments, and practicing with obstacle courses to gain real-world skills.

Conclusion

It is not only possible to master the skid steer loader controls in a few days but this mastery also becomes the basis for a safe, efficient, and fun operation. By learning the control patterns by heart, carrying out machine handling in a safe way, and also keeping on working with attachments and advanced moves, any operator is able to approach the heavy jobs with a great amount of self-assurance.

Always refer to the loader’s manual for any instructions that are specific to the model, give safety the highest priority, and never cease learning – the best operators are the ones who have mastered the basic skills and are still committed to their improvement.

For more detailed guides, loader reviews, and expert maintenance resources, don’t forget to keep skidsteerloader.net bookmarked and sign up for the latest compact equipment handling world updates.