Skid Steer vs. Compact Wheel Loader vs. Compact Track Loader: The Ultimate Comparison Guide for 2026

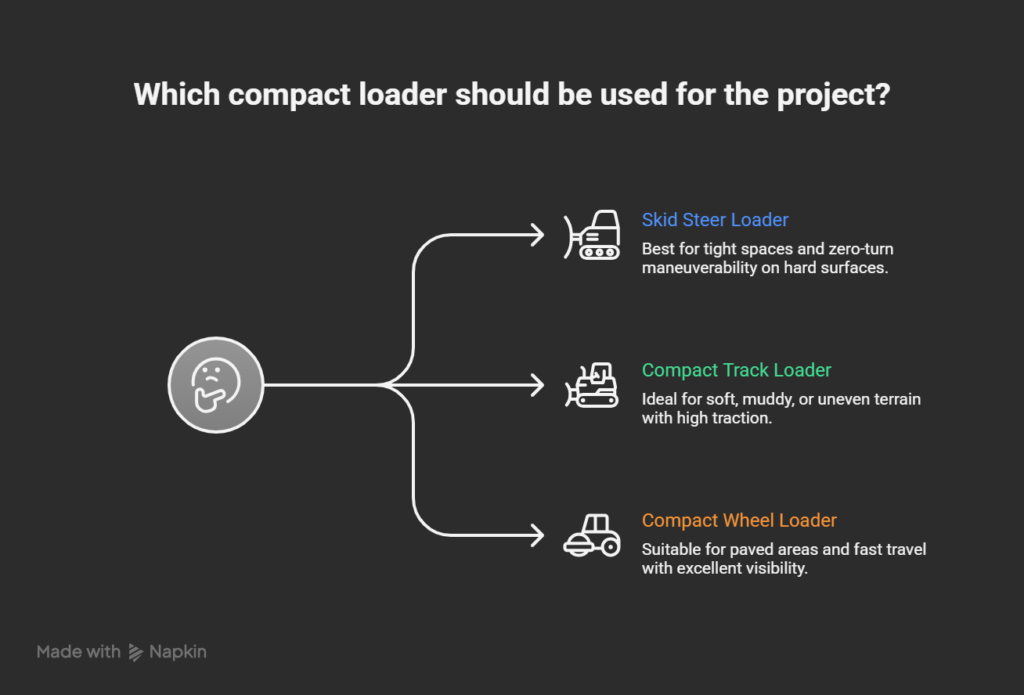

When there is a lot of heavy gear and construction going on, choosing the correct piece of equipment may make or break your project in terms of both time and money. Contractors, landscapers, and property managers sometimes have to choose between a Skid Steer, a Compact Wheel Loader, and a Compact Track Loader.

Each of this equipment has its own set of benefits for the job site, and each may make workplace productivity much higher in its own manner. It’s vitally crucial to know the distinctions between these machines, including how the skid steer can turn on a dime, the track loader can handle rough terrain, and the compact wheel loader can see and move quickly.

We at Skid Steer Loader want you to be able to make choices based on the information that are most important to you. This long guide will talk about what various machines can do, their pros and cons, and help you make smart decisions about how to spend your money and choose the best equipment for your company.

Features: Skid Steer vs. Compact Wheel Loader vs. Compact Track Loader

Skid Steer Loaders (SSL): The Agile Powerhouses

There is almost no other machine that is as versatile and maneuverable as a Skid Steer Loader or just Skid Steer. Skid steers are four wheeled machines with a unique steering system wherein the wheels on the left and right sides can be operated separately, which means the machine will turn by skidding its wheels and can even spin around itself!

This zero-turn radius capability makes them indispensable in your projects when space is so tight that large equipment simply won’t fit. Skid steers tend to be lighter than their track loader counterparts and are also famous for their speed on hard surfaces such as concrete and asphalt.

They have become the first choice for urban demolition, street repair, and material handling tasks. Besides that, there is an immense range of attachments available in the market, such as hydraulic breakers, augers, etc., that can easily turn these simple machines into multi-purpose tools for any given job.

- Cost-Effectiveness: The initial purchase price of skid steers is usually lower and these machines have cheaper maintenance costs compared to track loaders, mostly because the replacement of tires is cheaper than that of tracks and other undercarriage components.

- Hard Surface Performance: They do best on paved surfaces, asphalt, and concrete, getting around quickly and smoothly without the wear and tear that tracks would endure on such abrasive surfaces.

- Unmatched Maneuverability: By spinning in place with counter-rotation, a driver can easily and comfortably get around a congested work site or even a narrow passageway.

Compact Track Loaders (CTL): Masters of Soft Terrain

Compact Track Loaders (CTLs) are nearly identical to skid steers in terms of frame and lift arm design, however, they take the wheel location and replace it with a rubber track undercarriage. This one major difference makes a world of difference in their use. Tracks give the machine a lot more ground contact area, lowering the ground pressure and giving the machine better flotation.

Hence, CTLs are the almost undisputed rulers of soft, muddy, sandy, or snowy terrains that would simply spell the downfall for a wheeled machine. Not only that, the increased stability given by tracks also results in a gentler ride on rough ground and often a higher lifting capacity compared to the machine’s size.

If your landscaping business is aiming for minimal ground disturbance or is focused on “turf-friendly” operations, you will still be better off with a compact track loader even if you consider the higher initial and maintenance costs of undercarriage.

- Superior Flotation: The tracks spread out the weight of the machine over a larger area, enabling it to “float” rather than sinking in mud, sand, or even deep snow.

- Enhanced Stability: The tracks provide a longer footprint that is sufficiently stable not only to lift heavy weights but also to be used on inclined surfaces where less stable wheeled machines would be scary.

- Minimal Ground Disturbance: CTLs leave less damage to finished lawns and to delicate surfaces, thus greatly reducing the need for extensive site repair once the job is complete.

Compact Wheel Loaders (CWL): Efficiency and Visibility

Compact Wheel Loaders meet right in the middle of skid steers and bigger heavy equipment. Unlike the other two which utilize skid-steering, CWLs most often have articulated steering where the machine bends in the middle. There are quite a few distinct benefits that this design brought about, especially with regards to operator comfort, visibility, and fuel efficiency.

Since the wheels turn instead of skidding, the tires get worn down much less and the engine doesn’t have to work as hard at changing direction, so the machine will be more fuel-efficient in long shifts. Operators’ seats are usually positioned higher up which allows them to easily see the bucket and all around the work area – something very important to safety in busy environments.

While their turn may be not as sharp as a skid steer, their high-speed travel and ability to carry heavy loads even over long distances make them perfect for loading trucks, pallet moving, and snow removal in big parking lots.

- Extended Tire Life: The tires are not being scrubbed or skidded against the ground due to the articulated steering, so the lifespan of the tires is greatly extended, and this consequently leads to a reduction in operating costs.

- Fuel Efficiency: Less power is wasted in the steering process, which is why CWLs normally consume less fuel as compared to skid steers and track loaders.

- High Ground Speed: These machines are usually faster, therefore, they are more efficient when it comes to “load and carry” applications where materials need to be transported over large sites.

Comparative Analysis: Choosing the Right Machine

The choice between a Skid Steer vs. Compact Wheel Loader vs. Compact Track Loader is often narrowed down to the nature of your work tasks. Say you do demolition work on concrete, then the skid steer would be your perfect match.

If landscaping is your thing and you’re working during the rainy season or clearing a piece of land, then a track loader is what you really need. A compact wheel loader is the right choice for municipal work or large material handling yards. Here is a cheat sheet to help you compare and contrast.

Table: Comparison Skid Steer vs. Compact Wheel Loader vs. Compact Track Loader

| Feature | Skid Steer Loader (SSL) | Compact Track Loader (CTL) | Compact Wheel Loader (CWL) |

| Steering | Skidding (Zero-Turn) | Skidding (Zero-Turn) | Articulated (Pivot) |

| Terrain | Hard, Compact, Paved | Soft, Muddy, Uneven, Sloped | Paved, Dirt, Level Ground |

| Speed | Moderate to Fast | Slow to Moderate | Fast |

| Tire/Track Wear | High (on abrasive surfaces) | High (on hard surfaces) | Low |

| Initial Cost | Low | High | Moderate to High |

| Maintenance | Low to Moderate | High (Undercarriage) | Low to Moderate |

| Visibility | Limited Rear/Side | Limited Rear/Side | Excellent |

FAQs: Skid Steer vs. Compact Wheel Loader vs. Compact Track Loader

What differentiates a skid steer from a compact track loader the most?

The biggest difference is the type of undercarriage. Skid steers are equipped with wheels which makes them run faster and be more effective on hard surfaces, whereas compact track loaders feature tracks that provide better flotation and traction on soft or uneven grounds.

Which loader would be an ideal choice for snow removal?

Normally, skid steers would be the choice for snow removal on pavement because their tires enhance ground pressure when scraping the ice and they also can move around quickly. On the other hand, in the case of deep snow or unpaved areas, compact track loader’s traction is the best. Compact wheel loaders can be great for piling snow in large parking lots.

Are maintenance costs for compact track loaders higher than those for skid steers?

Generally, yes. A compact track loader’s undercarriage includes more components (idler, sprockets, tracks) which tend to require replacement more often and are quite expensive, especially when used on abrasive surfaces. For a skid steer, tire maintenance is the main concern.

Are the same attachments compatible with all three machines?

Pretty much yes. Skid steers and compact track loaders often have the same quick-attach plate. Compact wheel loaders normally come with a skid-steer coupler option, thereby becoming compatible with most hydraulic attachments used on the other two machines; thus, hydraulic flow rates have to be checked.

Which equipment has the highest resale value?

Compact track loaders are currently experiencing a very high resale value because of their great popularity in the construction and landscaping industries. Still, compact wheel loaders that are well-maintained also have good resale value due to their long component life.

Is a compact wheel loader safer than a skid steer?

One of the reasons why many operators consider compact wheel loaders safer is their excellent visibility. The better 360-degree viewing ability helps to reduce blind spots and comes the higher seating position and no lift arms positioned right beside the cab windows (in some designs). This feature is even more evident when compared with the enclosed “cage” of some skid-steers.

What are the criteria for choosing a machine that is right for my business?

Think about the type of terrain you most often work on (hard or soft), consider your budget (upfront vs. long-term maintenance), and check if there is little room to move around. If tight urban-confined spaces are your working environment, choose a skid steer. If you work in muddy areas and woods, pick a track loader. If you load trucks in a yard, wheel loaders are your tool.

Choose Wisely: Skid Steer vs. Compact Wheel Loader vs. Compact Track Loader

Although we have been discussing the advantages of Skid Steer vs. Compact Wheel Loader vs. Compact Track Loader, the truth is, there is no one machine that will be the best for everything but rather the one that will be best suited to your application. By comparing pros and cons related to the maneuverability, terrain capability, and operating costs, you’ll be sure that your purchasing decision will result in higher profit and efficiency.

At Skid Steer Loader, we want to be your companion in this journey by offering expert advice, useful tips on safety, and news about the latest trends in the industry. Our wide array of resources cover latest attachment reviews for 2026, winter maintenance tips, and many other topics that will keep your business growing.