Universal Pallet Forks for Skid Steer

Introduction: The All-Purpose of Material Handling

The growth of the construction, agriculture, landscaping, and warehousing industries depends on the productivity of the employees, and as such, the tools they are using. Pallet forks like those made for skid steer loaders belong to the group of most frequently used and indispensable machines—powerful yet cost-effective, easy to operate.

If you intend to move different loads such as wood, bales, fire bricks, or packages, you should know that pallet forks can do the job that you were expecting from a dozer. Suchlike tools are able to convert your skid steer for various operations.

In this article, we will see how through the use of pallet forks which are very strong tools, you can be able to change all loading and transportation procedures efficiently, and at the same time, you are able to redraw labor and recover the worth of your business.

Description of Universal Pallet Forks

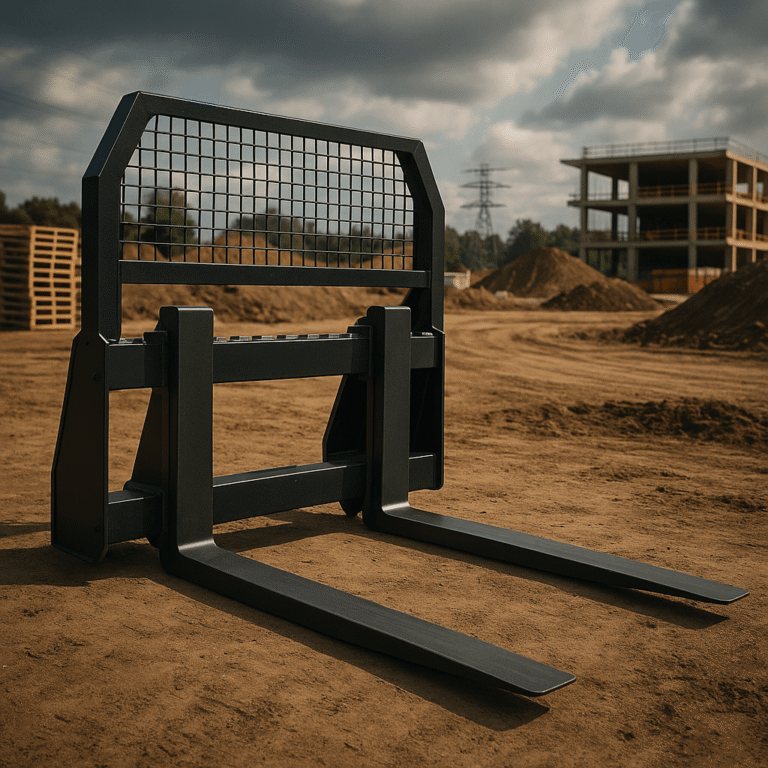

When we talk about universal pallet forks we are referring to a piece of machinery that can be attached to a skid steer loader and lift weights with great accuracy and freedom of movement. They normally consist of a solid steel frame and a two-tine fork, which are easy to adjust. Skid-steer universal pallet forks are called “universal” because they use a certain type of attachment system, for example the universal quick attach or SSQA (Skid Steer Quick Attach) meaning they are adaptable to a large number of skid steers.

From hay bales on a farm to concrete blocks on a construction site, pallet forks manage a massive workload of assignments. They are simple to use and their worth lies in the fact that there are no hydraulics, electronics or any other kind of technical advancement – only the mechanical force required coupled with the highest level of comfort and usability.

Advantages of Using Pallet Forks on Skid Steers

Enhanced Loading Capabilities

The first and main point to note about universal pallet forks is that they are capable of lifting and transferring goods the safest and the most efficient way. Unlike bucket attachments, the pallet forks enable a user to completely move the products by just going beneath them, without moving them, and it’s perfect for loading the pallet truck with gyro box products.

Using pallet forks for unloading or loading is a very secure way to ensure stability and that there will be minimized chances for items to fall over and trip over—especially when the right load backrests are applied to them.

Versatility Across Industries

Pallet forks for skid steers are utilized in various sectors in such instances where they are required:

Possessing the qualification of lifting pallets, construction contractors are involved in changing the location of bricks, cement bags, and lumber.

Truck-sized areas that are designed for packaging and processing of farm products often find multiple uses including:

- Carrying the weight and moving around in the storage area for grain.

- Landscaping companies are provided with hydroseed and other vegetation for:

- Easily spreading the mulch over unevenly produced flower beds in a most professional way.

Several UK online reclosable bags stores give you the opportunity of carrying and storing your fishing baits or operating in the food industry.

Many of these are compatible with most of the main skid steer brands; therefore, it is possible to use one set of forks on more than one machine within a fleet.

Labor and Time Efficiency

It’s been said over and over that time equals money. Manually lifting, pushing, or using carts instead of a pallet jack is not only slow in this highly competitive world, but it also exposes workers to accidents.

Pallet forks consequently reduce the removal of manpower and increase the speed for the movement of materials. Also, they provide workers with safe and healthy.

Forklift-like features for your skid steer can now provide off-road capability in rough terrain. In this case, you too can benefit from forklift advantages like those that traditional forklifts cannot match in such areas.

Choosing the Right Forks for Your Skid Steer:

Weight Capacity:

Always pick forks that can hold more than your heaviest potential load. Standard forks are rated in the range from 2,000 lbs to 6,000 lbs capacity, but there are those for heavy-duty applications that can even go beyond 10,000 lbs. Overloading can be detrimental to the attachment as well as the skid steer, or in the worst scenario, it can even lead to accidents.

Fork Length:

In general, fork dimensions are in the range from 36” to 72”. Shorter forks help in maneuvering better in limited spaces, while longer forks enable the lifting of bigger items on the top shelf. Yet, during the attachment of the latter, it is all about rule one ‘look out for the center of gravity’.

Frame Design:

You should stick to forks with a robust frame made of reinforced steel and a universal quick-attach mount. Most frames, in addition to side reinforcement, can also be fitted with a back tongue or a front grid to prevent any fall-back of the cargo to the cab.

Adjustability:

The possibility of the adjustable fork spacing feature makes the scenario much better. In general, forks can be moved along the carriage, which makes it easier for the allocation of space irrespective of the load size. Locking pins make certain the forks do not disengage during transport.

Application Scenarios: Real-World Use Cases

Jobsite Supply Delivery

Think of a construction site that is affluent with action. On the one hand, trucks with building materials, such as plasterboards, cement, or roofing materials, are on the way, while on the other hand, the workers are busy fixing the scaffolds. By using the pallet forks, the skid steer can put the work of unloading the truck on a fast track, thus having much more work done and distribute the materials wherever they are needed without any loss of time—a task that only a forklift, which is readily available at the site, could perform.

Farm Operations

Farmers use pallet forks for everything from transporting feed and hay to lifting farm equipment or fencing supplies. The skid steer equipped with pallet forks becomes a good companion of the farmer if he or she has to abstain from driving a traditional forklift through the dirt-puddles.

Landscaping Projects

Landscapers are usually the very people who are to carry the heavy goods e.g. stone pavers, retaining wall blocks, or rolls of turf. Thanks to a pallet fork, the loading and distribution tasks are no longer a hassle for a single operator who can handle the tasks that normally require more workers without any difficulty.

Maintenance and Safety Tips

Regular Inspections

Inspect the forks for bending, cracks, or weld failure both before and after using. Another critical point is to make sure the locking mechanisms and attachment points tightly and securely fix the forks to the skid steer loader.

Safe Operation Guidelines

- Never exceed the rated weight capacity.

- Always load with an even weight distribution.

- Keep loads low when moving.

- Travel slowly on uneven or inclined surfaces.

- Wear backrest guards to protect your safety from falling backwards.

After work, a safety inspection is not only for the machinery but for the worker himself.

Environmental Compatibility

Forklifts appear to be less efficient at work outdoors, but skid steers armed with pallet forks certainly can handle that part—gravel yards, overloaded farms, worksites covered with snow, or even constricted and packed city alleys. As auxiliary units, the compact size and all-terrain drive of skid steer loaders bring a tremendous benefit to the industrial, commercial, and farming sectors as well as the relatives in between.

In addition, reducing environmental impact by cutting fuel consumption and redundant equipment usage can be achieved by employing one single machine for different purposes.

Boosting ROI with the Right Fork Attachment

By purchasing universal pallet forks a skid steer owner undoubtedly makes the most cost-efficient move. It transforms a loader into a lift-and-carry machine that can replace forklifts in a considerable number of situations. The attachment is low on maintenance, has a long life, and its resale value is quite high.

Additionally, that they can do a wide range of operations for a long period of time without any interruption guarantees you get a good ROI on each penny expenditure.

Why Skid Steer Owners Trust Universal Forks

Skid steer owners mainly prefer simplicity of design, adaptability to various machine models, and the ultimate level of construction durability. And pallet forks are the answer. Their robustness, the fact that they can be used across multiple brands, and easy handling without any extra features make them the top tool for professionals who know how to get the job done once.

Many of you might be looking to get your first attachment or wanting to complement the rest of your fleet, but one thing is for sure: forks are those you will find indispensable in most situations.

FAQs

Can pallet forks fit any skid steer?

Sure. A universal quick-attach system (SSQA) is the one that is mostly used in current-day pallet forks, thus allowing them to be applied to the vast majority of skid steer loaders brands such as Typhon, Bobcat, Skidsteer loader, and Kubota, to name a few.

What’s the difference between skid steer pallet forks and forklift forks?

The two classes of promotional tools, skid steer pallet forks, and forklift forks both help in loading and unloading operations. Skid steer pallet forks are best to use in off-road circumstances and are far more robust to tolerate tough conditions. On the other hand, forklift forks are for smooth indoor use which is why they have limited ground clearance.

What fork length is best for my skid steer?

It mainly depends on the volume and the kind of ware you carry around combined with the conditions you are going to operate in. Standard forks are 48-inch long forks and they are good when it comes to reaching and allow the operator to have mobility in maneuvering the vehicle. When we have heavy duties the more extended 60-inch or 72-inch forks are enough. Larger jobs may require 60-inch or 72-inch forks.

Can I use pallet forks to lift non-pallet items?

Definitely. As long as you handle it with care, pallet forks can lift wood, pipes, steel beams, fencing, or even piles of rubble. However, ensure that the object that you are going to lift is balanced and secured to avoid any tipping or displacement of the load.

How do I maintain my pallet forks for a skid steer?

Monitor the condition of the tines and the frame systematically for signs of wear, rust, or impact damage. Besides, you should be lubricating any movable sections, wash away mud and other residues, and check the locking system before you start making use of it to ensure there is no defect. Whenever it is possible, store it indoors for its long life.

Final Thoughts: Load Smart, Work Smarter

In the material handling world, nothing comes close to universal pallet forks for skid steer in terms of their functionality and the way they have gotten everyone’s relish. They make difficult jobs so much easier to complete, less time-consuming, and not as demanding as far as physical labor is concerned. Plus, they are traceable from one job to another.

It doesn’t matter what occupation you are in, lift payloads safely, make jobs go quickly, and adapt to many different work settings with pallet forks. Even if you were a businessman, warehouse manager, or farmer, it is a must to buy a pair of good quality pallet forks. It’s just not an attachment—it is an asset.

Eager to provide your skid steer with the most efficient pallet forks?

Discover our handpicked collection of powerful, cost-effective, and universally compatible pallet forks at https://steerskid.com. Get smart. Go quickly. Carry easily.