Mastering Winter Skid Steer Operation: Top 5 Tips to Snow Removal

Once winter is here your good skid steer loader is not going to take a rest—it is going to be the most important machine for handling snow and ice. If you are the owner or operator of one of these tough machines, then you know that a successful winter loader operation is not a matter of chance; it is all about being prepared with our winter skid steer. Freezing weather, slippery ground, and deep snow can put your machine under a heavy strain.

Steps for Winter Skid Steer – Top 5 Snow Removal Tips

In case you overlook simple checking, you might break down at the moment when you badly need your skid steer. This blog will teach you the necessary steps to get your device ready for the cold so that you can have winter skid steer snow removal at a good level all the time. We will help you keep your work going smoothly, safely, and profitably.

Step 1: The Crucial Pre-Season Winterization Checklist

The success of winter is determined a few months before the very first snowflake. Winterization is the most significant moment in the process of getting your skid steer ready for a long period of cold. Low temperatures make all fluids thicker, batteries become less powerful, and parts made of rubber get hard.

- Mind Your Fluids: The Engine’s Lifeblood. Temperature below zero makes engine oil as well as hydraulic fluid that are usually utilized for machines to be thick and less mobile. Practically, it causes the engine and the hydraulic pump to be the hardest ones in the whole system. The solution is very simple: change to the synthetic, using low-viscosity, winter-grade engine oil (like a 5W-40), and do the same for the hydraulic fluid. It makes all fluids used in the machine become very flowy and without friction even at the deepest freezers.

- Check the Anti-Freeze: A hydrometer or refractometer helps you determine the freezing point of coolants. The one that keeps the engine cool at least is colder than the historical low-temperature of the area should be chosen. It is a must to use the winter-grade fluids only; running summer fluids in the cold will lead to engine damage very fast.

- Diesel Fuel: Preventing the Gel. In case your skid steer is a diesel one, please make sure you use diesel with a winter blend. It is a kind of fuel that comes with additives (like kerosene) to keep the wax components in the diesel from getting solidified or “gelling,” and as you know, this will abruptly clog the fuel lines. After a shift, you should always refill your fuel tank. By doing this, you lessen the area for the air to come in and thus prevent condensation from forming and freezing inside the tank.

Step 2: Securing Your Power: The Battery and Electrical System

That is why, under cold weather, battery power is halved when one tries to start a cold engine. In fact, the internal resistance is high for the engine, and thus it is difficult to start. At the same time, cold weather reduces your battery’s power output by up to half! You require the transistor to work at its peak capacity to ensure that the winter loader operation is performed without any problem.

- Test and Clean the Battery: Prior to winter, the battery’s Cold Cranking Amps (CCA) rating should be tested. In the case when it is weak, replace it immediately. Remove any white or blue corrosion from the terminals so that the connection is strong. A clean terminal guarantees that the maximum current reaches the starter.

- Use Heaters Strategically: Among outside-stored devices, your dearest friend is an engine block heater. Connect it an hour or two before the machine is on. By pre-heating the engine block, friction is drastically reduced, and the starter’s job becomes easier. Likewise, a battery blanket can help maintain one’s battery capacity at the highest level.

- Check Your Glow Plugs: If you are using a diesel engine, glow plugs or intake air heaters are very important for ignition. Check them to be sure they are heating properly. An unsuccessful glow plug means that’s it’s very hard, if not impossible, to start the engine when it is cold.

Step 3: Traction and Control: Getting a Grip on the Snow

The ground under the tires or tracks of the winter skid steer is the only connection that the machine has with the slick surface. Maximum traction is the key to effective skid steer snow removal and safety.

- Tires and Chains: As for a wheeled skid steer, one should constantly monitor the pressure of his/her tires. The reason is that the cold air will lower the pressure. Dedicated snow tires can be installed or, for the best grip on ice, the user of heavy-duty tire chains. Chains are a must if you are plowing for commercial purposes.

- Tracks and Undercarriage: If you are a Compact Track Loader (CTL) user, you should check the whole undercarriage. See if there are any cracks, worn areas, or loose bolts on the rollers and idlers. Frozen earth and covered up debris put a lot of pressure on these parts. Proper tread depth is very important for getting a good grip on snow and ice.

- Adding Counterweight: For better pushing power and stability, especially when using a large snow pusher, think of adding some weight on the back of the machine (ballast). This ensures that the grip of the machine is improved and it also stops the machine from becoming unsecured when the attachment is loaded with heavy snow.

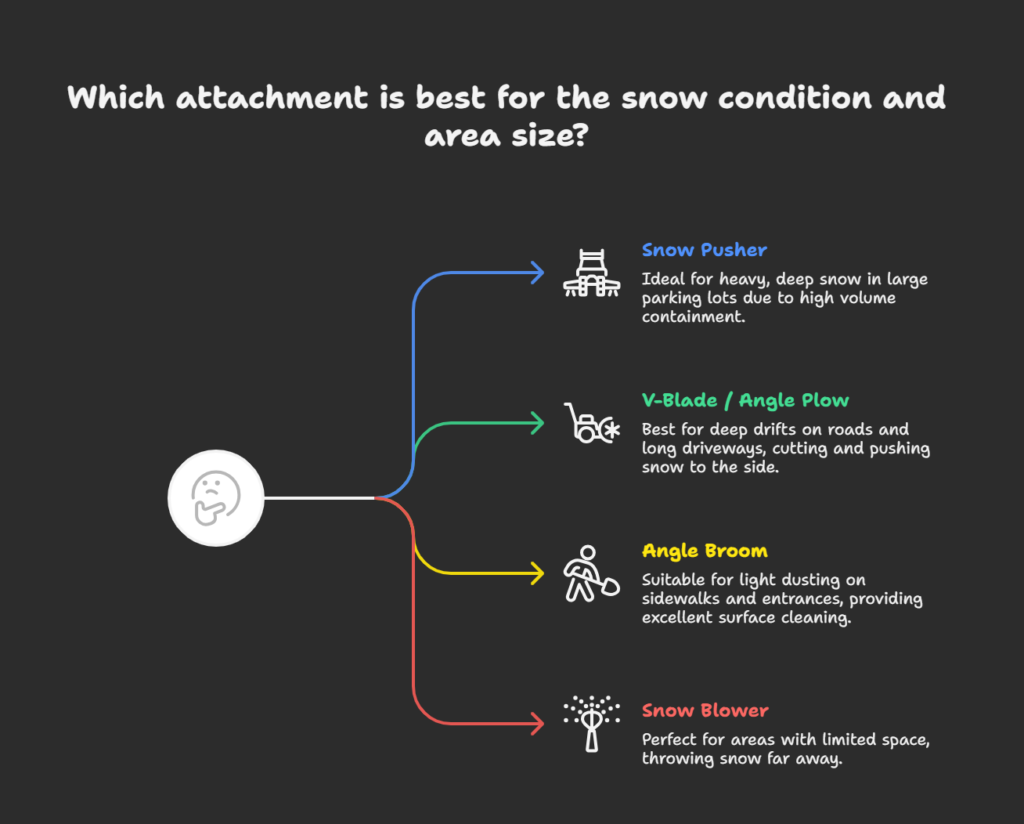

Step 4: Choosing the Right Snow Removal Tool

A skid steer is a multi-tool, but the right attachment has to be used. The wrong tool will do the job, but the time and fuel consumption will increase. Choose your attachment according to the work, the depth of the snow, and the surface you want to clear.

- The Go-To for Parking Lots: The snow pusher is the peerless tool for performing a mass-area cleaning job such as commercial parking lots. It quickly contains and moves huge volumes of snow, allowing you to clear an area fast. A rubber edge option should be looked for if there is a need to protect pavement and curb markings.

- Stacking and Drifting: High stacking or cutting of deep snow piles can be easily done by a hydraulically-controlled V-Blade (or Angle Plow). You can angle the blade to push snow to the side or use the V-shape to cut through heavy accumulations.

- The Finishing Tool: For sidewalks, entryways, or sensitive surfaces, the Angle Broom attachment is perfect. It sweeps away light snow, slush, or remaining debris, leaving a clean finish.

- Moving Snow Off-Site: When the only options left are pushing and stacking, and there is too much snow, then a powerful Snow Blower attachment should be your next step. The machine throws the snow far away which is perfect for places with small storage spaces.

Tabular Format – Snow Removal With Winter Skid Steer:

| Snow Condition | Recommended Attachment | Best for Area Size | Key Feature |

| Heavy, Deep Snow | Snow Pusher | Large Parking Lots | High volume containment |

| Deep Drifts | V-Blade / Angle Plow | Roads, Long Driveways | Cuts and pushes to the side |

| Light Dusting/Finish | Angle Broom | Sidewalks, Entrances | Excellent surface cleaning |

| Too much snow to store | Snow Blower | Anywhere with limited space | Throws snow far away |

Step 5: Safe and Smart Cold Weather Skid Steer Operation

Working in winter comes with problems such as poor visibility and slippery ground. The operator’s attention and good habits are a prerequisite for safety and efficiency.

- The Warm-Up Ritual: Never go straight to work after a start. The machine should be left to idle for 5 to 10 minutes at mid-throttle. Most of this time is needed for the engine and, to a greater extent, the hydraulic fluids to warm up and be able to circulate freely. Slow work of the lift arms and tilting the bucket a couple of times will also help to warm the hydraulic system. The rushing step is the one that wears out the seals and pumps prematurely.

- Keep Your Vision Clear: It is very important to be able to see. Before the commencement of works, make sure that the heater as well as the defroster of your cab is in good working condition. Confirm that all your working lights, headlights, and safety beacons are clean and bright. Your wiper blade and washer liquid should be used frequently as snow is accumulating rapidly.

- Smooth Movements Only: Use smooth and controlled throttle movements if you are pushing snow. Doing so is definitely a bad idea if you are rotating your tires or tracks as it is a counterproductive method – it agitates fuel, induces wear and in fact polishes the surface, thereby causing the ice underneath to become more slippery. In case you feel a slip, you should immediately stop pressing the accelerator. Also, always keep in mind that there may be dangers hidden under the snow such as fire hydrants or manholes.

- Post-Shift Clean-Up: Your work is not done after the machine is turned off. Spend a few minutes ridding the undercarriage, track systems, and hydraulic cylinders of all the compacted snow and ice. If snow is allowed to melt and then refreeze overnight, it can cause the seizing of components, tearing of seals and, as a result, making your next morning a disaster. It is better to put the machine indoors or under some sort of cover when it is not in use.

Winter Skid Steer FAQs

What is the best skid steer attachment for heavy snow removal in a large parking lot?

Nothing is better than the Snow Pusher. It was made to handle and relocate massive quantities of fresh ones very fast in just one simple go without any surface damage.

How do I prevent diesel fuel from gelling in my skid steer during extreme cold?

Winter-blend diesel fuel with anti-gel additives should be used and Fuel Tank maintenance should also be given utmost consideration. Condensation, which is the main cause of gelling, is less likely to occur when the tank is full.

Should I change my skid steer’s hydraulic fluid for the winter season?

Certainly! Lower viscosity winter-grade or synthetic hydraulic fluid should be used. Not only that but the hydraulics will also be kept fast and responsive in chilly conditions and the pump will be protected from being overworked.

Why does my skid steer lose power or run slowly in very cold?

Mostly it is that the fluids thicken which leads to power loss that the largest part are the engine and hydraulic systems are forced to work harder in such a case. They should use winter fluids and carry out a full warm-up for 5-10 minutes to solve the problem.

Are the tires or tracks better for a skid steer that will mainly be used for snow removal?

A wheeled skid steer with tire chains would definitely be faster on the pavement. Still, tracked skid steer (CTLs) will provide better flotation, stability, and grip in deep and uneven snow or on soft, unpaved terrains.

How long should I warm my skid steer up before using it in freezing temperatures?

At half throttle, the machine should be allowed to idle for not less than 5-10 minutes. The primary purpose of this operation is the hydraulic fluid is forcibly circulated and warmed so internal parts are protected from wear.

What is the most important daily maintenance check in a winter skid steer?

The one that involves the removal of all packed snow and ice from the undercarriage, joints, and cylinder rods after every shift so as not to freeze, bind, and cause damage during the night is the most important of them all.

Final Thoughts: Your Advantage in the Cold

Winter should not be the reason for you to slow down. By agreeing to follow these preparation and operating rules, you turn the cold weather challenge into a great opportunity for your business. Getting a winter skid steer loader operation skill level not only saves your investment but also guarantees the meeting of the most important deadlines and the safety of your operators.

So, act in advance, be ready, and keep your profits up this season with winter skid steer. If you want to get more professional tips and resources for maximizing your machinery, do not forget to come back to skidsteerloader.org.