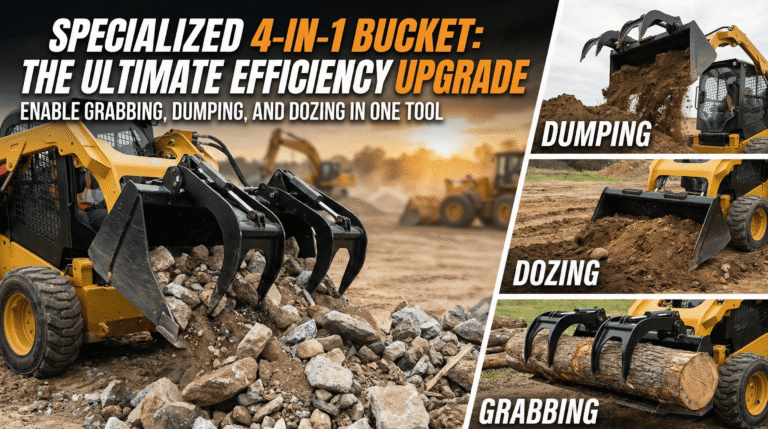

Specialized 4-in-1 Bucket Enable Grabbing, Dumping, and Dozing in One Tool: The Ultimate Efficiency Upgrade

Whether it’s construction, landscaping or even industrial site management, efficiency is the very essence of the business. Each time operators halt the machinery, switch-off the engine, get out of the vehicle and change the attachments manual, precious minutes go missing. Those minutes will add up to hours of lost productivity in the span of one week or month. For that matter, it is a real game changer specialized skid steer 4-in-1 bucket.

Compared to normal buckets that are mainly intended for loading and unloading materials, a 4-in-1 bucket is a hydraulically powered device that converts your skid steer, track loader, or telehandler into a high performance versatile equipment. By syncing the functionalities of a bucket, a grapple, a dozer, and a scraper in one single attachment, such a tool enables change of different works without getting off the cab.

If clearing site debris for demolition, driveway grading, or handling bulky logs – these are just three different methods by which grabbing, dumping, and dozing can be done within one smooth working motion through this specialized tool.

What is so special about 4-in-1 bucket?

It is mainly its outstanding capability in performance that is engineered touching every piece of the gadget you got at in your collection. Alongside its simple yet powerful clam option, component-wise there are powerful heavy-duty hydraulic cylinders backing up the design. The trick to the binding is its operation when it opens up by splitting the top and the sides separately from the back.

Working closed, it behaves exactly like a well-built ordinary bucket with great digging breakout force. While with a tweak of opacity, it can come out as a grapple able to clamping pressure securely on irregular shaped objects. Further opening the bucket sides to their limit turns its back of becomes a bulldozer for pushing earth or snow. Additionally, the rear edge can be activated to get a scraper or leveler.

If you, as a fleet operator or a small independent contractor, are searching for a solution to increase your operational efficiency via 4-in-1 buckets, it is like going through different aspects of skidsteerloader.org and finding the best match that corresponds to your type of elevated work.

Therefore, once you have decided on the right Skid Steers for your work at elevated height, applying the same thought process to ground level, a multi-functional bucket is the way to go.

The Mechanics of Versatility: How It Works

To properly understand the advantages brought by the 4-in-1 bucket it is proper to figure out how deeply they integrate hydraulics. The machine’s auxiliary hydraulic system, to which the attachment is connected, provides an interface that allows the operator to exercise at will the opening/closing function.

Contrary to what a monolithic opening and closing operation may imply, hydraulics have here been designed to meter the flow so as to allow both extremely delicate operations such as lifting only one large rock without crushing it, as well as very aggressive ones like crushing thick roots.

- Hydraulic Precision: The auxiliary hydraulic system allows for feathering the controls, meaning operators can adjust the clamping force in real-time to suit the material being handled.

- Structural Reinforcement: Key stress points, such as the hinge pins and the dozer cutting edge, are typically hardened to prevent warping under heavy loads.

- Universal Mounting: Most modern 4-in-1 buckets come with universal quick-attach plates, making them compatible with a vast array of skid steers and track loaders from different manufacturers.

Functionalities of 4-in-1 Bucket

1. Function 1: The Dozing and Grading Capability

The 4-in-1 bucket has most versatile functions that along with grading can be counted among the list of dozing and bulldozing capabilities. Opening the clam fully, the rear dozer blade is exposed to the operator for use. This blade is in most cases furnished with a reversible, bolt-on cutting edge that excels in chopping dirt and pushing it with a lot of force. Hence, by virtue of this converting facility, a mini bulldozer can be stripped from a small size front loader, which can do tasks such as topsoil stripping, trench filling, and snow piling with the utmost ease.

- Better Visibility: The operator’s line of sight is greatly improved by the fact that the bucket’s front has been raised out of the way, allowing precision grading which is tough to do with a normal solid bucket where you are required to guess the position of the leading edge.

- Variable Blade Angles: Loaders’ arms can be tilted to alter the angle of the dozer blade, enabling either aggressive cutting or smooth finishing passes.

- Cost Savings: Reduces the cost of small to medium-sized grading projects by avoiding bulldozer rental or transportation expenses.

2. Function 2: The Grappling and Clamping Power

The grabbing functionality of the 4-in-1 bucket is considered as a major distinguishing factor compared to a standard dirt-bucket. Normally, one has to use a grapple attachment when handling remains of the tree-stump, broken concrete and the scrap metal for demolition and landscaping works as they are different in shape, size and might be heavy too.

However, the same 4-in-1 bucket can be converted to a grapple anytime by just opening the jaws, positioning the jaws over the object to hold and closing the jaws again. There are hydraulic cylinders embedded in the jaws, which produce the clamping force of thousands of pounds, hence ensuring the load to be secured in the nutshell during transportation.

- Secure Debris Handling: The clamping action prevents oddly shaped items like rocks, logs, and rebar from falling out of the bucket during transit, enhancing site safety.

- High Clamping Force: Powerful hydraulic cylinders deliver enough pressure to grip heavy objects securely or even snap smaller wooden debris for easier disposal.

- Dual-Edge Design: Many 4-in-1 buckets feature serrated side edges on the clam, which help to bite into logs or slippery debris for an even tighter grip.

3. Function 3: The Loading and High-Dumping Advantage

Even though a 4-in-1 bucket specializes in handling different works it is also a thoroughly good loading tool that can come handy at anytime. Drawing a comparison, a bucket in its shut position cannot hold anything more than the closed capacity of the bucket itself.

Getting high on your dump bed, a usual bucket would require you to first lift the arms till the dump bed top and then tip the bucket forward. You can consign the job to the 4-in-1 bucket as it simply requires you to place the bucket over the dump truck and pop the jaws (lid) to empty what is in there.

Thereby making dumping at heights which are normally not allowed by machines hottest pin is with the standard tip-dump action.

- Increased Dump Height: The bottom-dump feature allows operators to clear higher truck sides or hopper edges that would be impossible to reach with a standard roll-dump bucket.

- cleaner Material Release: Sticky materials that cling to the inside of a standard bucket fall away easily when the bottom is opened, reducing the need to shake the loader arms.

- Precise Placement: Operators can partially open the clam to dribble material out slowly, which is perfect for backfilling small trenches or distributing mulch evenly.

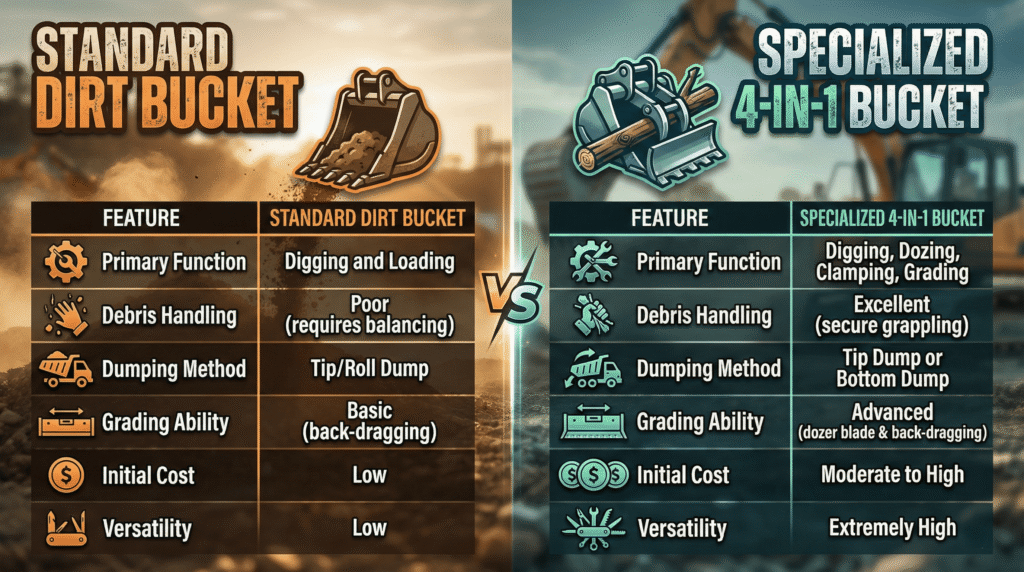

Comparison: Standard Bucket vs. 4-in-1 Bucket

Let us compare a standard bucket versus a 4-in-1 bucket so as to better grasp the differences and perceive more value in ones acquisition. Standard bucket as well as a product caters to a niche market: only one function is effectively done-the moving of loose material. Whereas the multi-purpose bucket is capable of multitude of outdoor pursuits.

For a site like skidsteerloader.org that is into raising awareness about the availability of the correct equipment in order that work can be safely and efficiently carried out , hence it is adopting this ground-engagement tool being the most rational step consistent with their goal for professional site management.

| Feature | Standard Dirt Bucket | Specialized 4-in-1 Bucket |

| Primary Function | Digging and Loading | Digging, Dozing, Clamping, Grading |

| Debris Handling | Poor (requires balancing) | Excellent (secure grappling) |

| Dumping Method | Tip/Roll Dump | Tip Dump or Bottom Dump |

| Grading Ability | Basic (back-dragging) | Advanced (dozer blade & back-dragging) |

| Initial Cost | Low | Moderate to High |

| Versatility | Low | Extremely High |

Operating safety is of utmost importance when dealing with complex hydraulic parts. During operation of a 4-in-1 bucket, which is capable of exerting large loads and moving parts operator should always be in the alert mode to prevent accidents. One should never put hands or use tools inside clam mechanism while it is powered by hydraulics.

Moreover, because the bucket weighs more than a standard bucket, operators must be mindful of the change in the machine’s tipping load capacity. Maintenance is equally important; the additional hinges and cylinders result in more grease points. Continual application of grease will make the clam move with no resistance thus preventing the premature wear of the pivot pins. Scanning the hydraulic hoses for signs of abrasion or leakage should be part of the daily pre-start check so that the tool remains dependable over the years.

- Load Capacity Awareness: The added weight of the hydraulic cylinders and reinforced steel reduces the overall lifting capacity of the loader, which operators must account for to prevent tipping.

- Pinch Point Hazards: The closing action of the clam creates dangerous pinch points; strict safety zones must be enforced around the front of the machine during operation.

- Routine Greasing: Multiple pivot points require daily greasing to flush out dirt and maintain smooth operation, especially in gritty construction environments.

FAQs About 4-in-1 Buckets

What is a 4-in-1 bucket used for?

A highly versatile piece of equipment, 4-in-1 bucket can perform four basic operations: digging, loading, bulldozing and grappling. More specifically, the operator is able to scoop up the soil, work a surface by grading it like a bulldozer, clamp to the objects like the logs or concrete pieces for grabbing and finally distribute the material evenly. In essence, single piece of equipment trumps typically three tools – bucket, grapple, and blade – all at once.

Can I use a 4-in-1 bucket for grading?

Absolutely, grading is one of its greatest strengths. It is through the act of opening the scene that the forgotten sub part has now been activated to function as a dozer blade. Accordingly, you are able to push earth forward, and cut or fill up spots top-down with better visual and command control than the simple bucket can offer.

How does the hydraulic system on a 4-in-1 bucket work?

Hydraulic cylinders control the opening and closing of the bucket’s “clam” that are connected to the loader’s auxiliary hydraulic system. The operator controls this movement from the cab so that it is practically instantaneous switching between bucket mode (closed) and dozer/grapple mode (open).

Is a 4-in-1 bucket worth the extra cost?

By and large, the answer would be in the affirmative. Despite being more costly than a standard bucket, it obviates the need for purchasing or renting a separate grapple and a dozer blade. Hence, not only does it save time in attachment changeover, but also increasing the diversity of tasks that can be completed by a single machine usually results in a quick payback.

What is the difference between a standard bucket and a 4-in-1 bucket?

The major difference lies in the fact that a standard bucket cannot mechanically change its shape/use. It is simply a solid unit that can only be used for excavating and dumping. On the other hand, a 4-in-1 bucket is a hinged one that can be opened; which allows it to bottom-dump for extra height, clamp onto debris, and act as a dozer blade, therefore offering four features rather than just one.

Do 4-in-1 buckets require special maintenance?

Compared to the standard buckets, they definitely require more care. The reason being that moving parts (hinges and cylinders) have brought about additional grease points, which normally have to be lubricated on a regular basis. Moreover, one shall always check the hydraulic hoses and fittings for any signs of damage or leakage.

Can a 4-in-1 bucket fit on any skid steer?

Most 4-in-1 buckets are equipped with a “Universal Quick Attach” system, which makes them compatible with the majority of modern skid steers and track loaders (like Bobcat, CAT, Kubota, etc.). However, you must ensure that the bucket’s weight does not exceed your machine’s operating capacity and that the hydraulic couplers match.

A Perfect Match – 4-in-1 Bucket

Conclusion Inevitably, the 4-in-1 bucket is much more than just an add-on; it is a weapon of increasing potential for any building or landscaping task. The combination of grabbing-dumping-dozing in a single tool strikes at the heart of the predicament faced by today’s construction sites: the demand for speed, safety, and versatility.

Just like skidsteerloader.org promotes the use of specialized, safe and efficient equipment for working at height, owning a specialized ground-engagement tool would mean that your operations at the surface level are equally efficient and therefore optimized. No matter if you are a skilled operator or an equipment manager, the capacity to adjust to the changing environment of the site without getting off the cab is an overwhelmingly significant advantage.

From the facially simple to the technically complicated: precise dozing to secure grappling, the bucket of such a specialty is what you should take stock of whenever the workload becomes rather heavy.